المدونة

أنواع الطوب

أنواع الطوب

أنواع الطوب

! تعرّف على خصائص واستخدامات الأنواع المختلفة من الطوب

منذ القدم، كان من الاحتياجات الأساسية للإنسان امتلاك مأوى آمن للعيش فيه، وقد أدى ذلك إلى ابتكار منتج عملي يُعرف بالطوب، والذي يتوفر اليوم بأنواع متعددة واستخدامات متنوعة. في الوقت الحاضر، توجد أنواع كثيرة من الطوب، يتميز كل نوع منها بخصائص محددة واستخدامات خاصة في أجزاء مختلفة من البناء. تابع معنا للتعرّف بالتفصيل على أنواع الطوب المختلفة واستخداماتها.

ما هو الطوب؟

أولًا، لنتعرّف على المقصود بالطوب قبل استعراض أنواعه. يُقصد بالطوب وحدات بنائية تُصنع من الطين أو الحجر، ويتم ربطها ببعضها البعض أثناء البناء باستخدام المونة.

مقال مقترح: اقرأ المزيد في مقال ما هو الطوب؟

أنواع الطوب واستخداماته

فيما يلي نستعرض أنواع الطوب المختلفة، واستخداماتها في البناء، وخصائصها المميِّزة مثل الأبعاد والوزن والمظهر.

-

طوب الليغو

يُعد طوب الليغو من أحدث أنواع الطوب، وقد لفت في الآونة الأخيرة انتباه المقاولين ومالكي الأراضي لبناء منشآت قوية وجميلة. يُصنَع طوب الليغو باستخدام مخلفات مناجم الرمل والحصى أو مصانع تقطيع الحجر، إلى جانب مسحوق الحجر والإسمنت، مما يمنحه مقاومة عالية. كما يحتوي هذا الطوب على ثقبين، ولكل جانب نتوءات وتجويفات تسمح بتشابك الطوب معًا، مما يُلغي الحاجة إلى استخدام المونة.

يُنتَج طوب الليغو بأشكال وأحجام متنوعة، ويُستخدم في بناء المنازل، والمسابح، والجلسات، والأسوار المحيطة. (للمزيد من المعلومات حول هذا الطوب المميز، اقرأ مقال:ما هي الطوب اللیغو؟”)

-

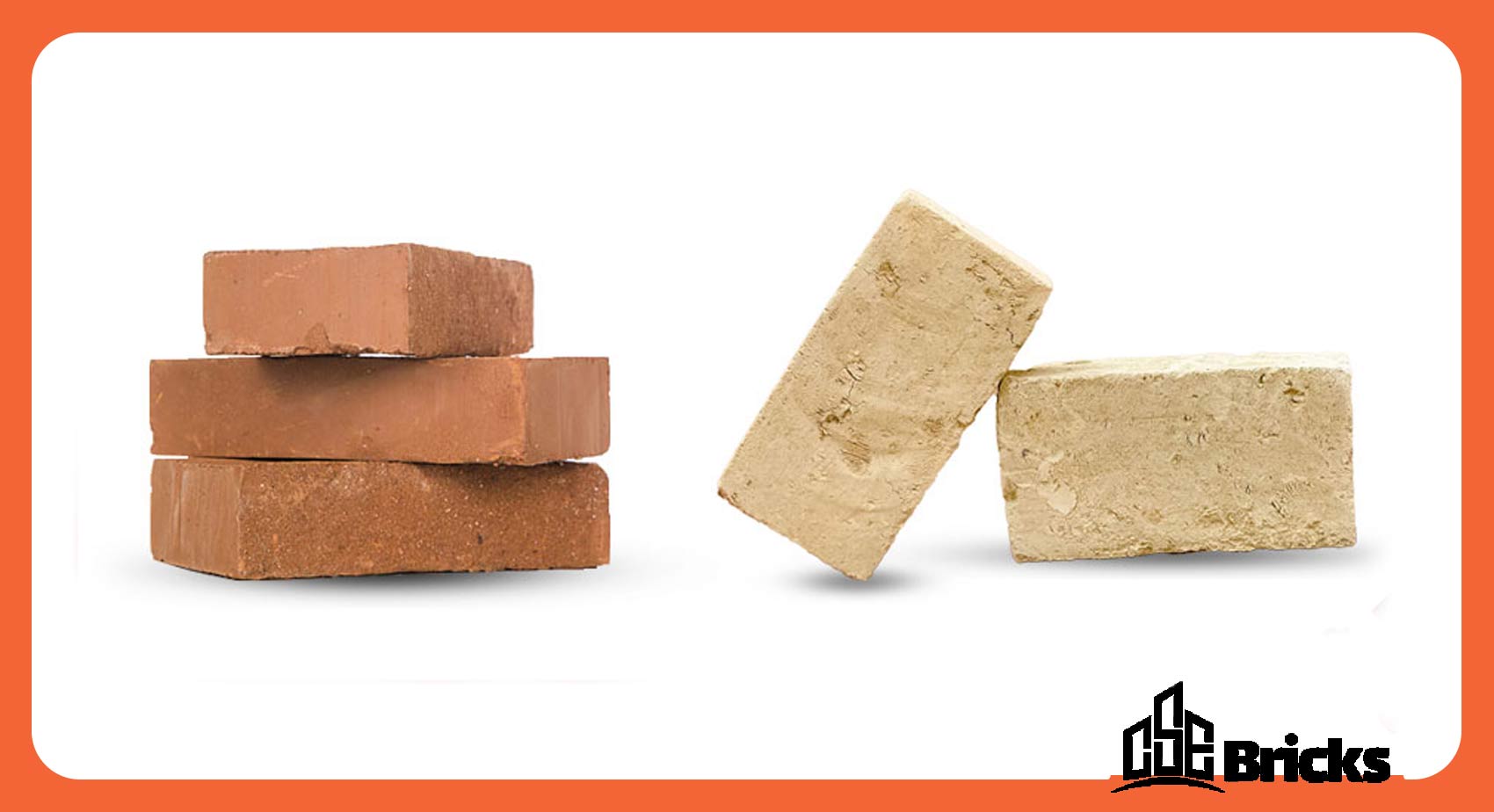

الطوب المضغوط

يُعد الطوب المضغوط من أكثر أنواع الطوب استخدامًا في البناء. يتم تصنيع هذا الطوب في الأفران، وسُمّي بالطوب المضغوطلأن زواياه تُضغط بالأصابع عند تشكيل الطين يدويًا. ومن أسمائه الأخرى: الطوب المصمت، والطوب الخشن، والطوب الكازاخي، وطوب غاري. يبلغ وزن كل طوبة مضغوطة حوالي 2 كغ، أي ما يعادل نحو 1700 كغ لكل متر مربع. وتبلغ أبعاد الطوبة المضغوطة 22 × 10 × 5.5 سم. يتوفر هذا النوع من الطوب في الأسواق باللون الأحمر أو الأصفر أو بمزيج من اللونين. ويُستخدم الطوب المضغوط في بناء الجدران الفاصلة، والجدران الحاملة للمباني، والأسقف المقوسة، وتكسية جدران الطوابق السفلية.

-

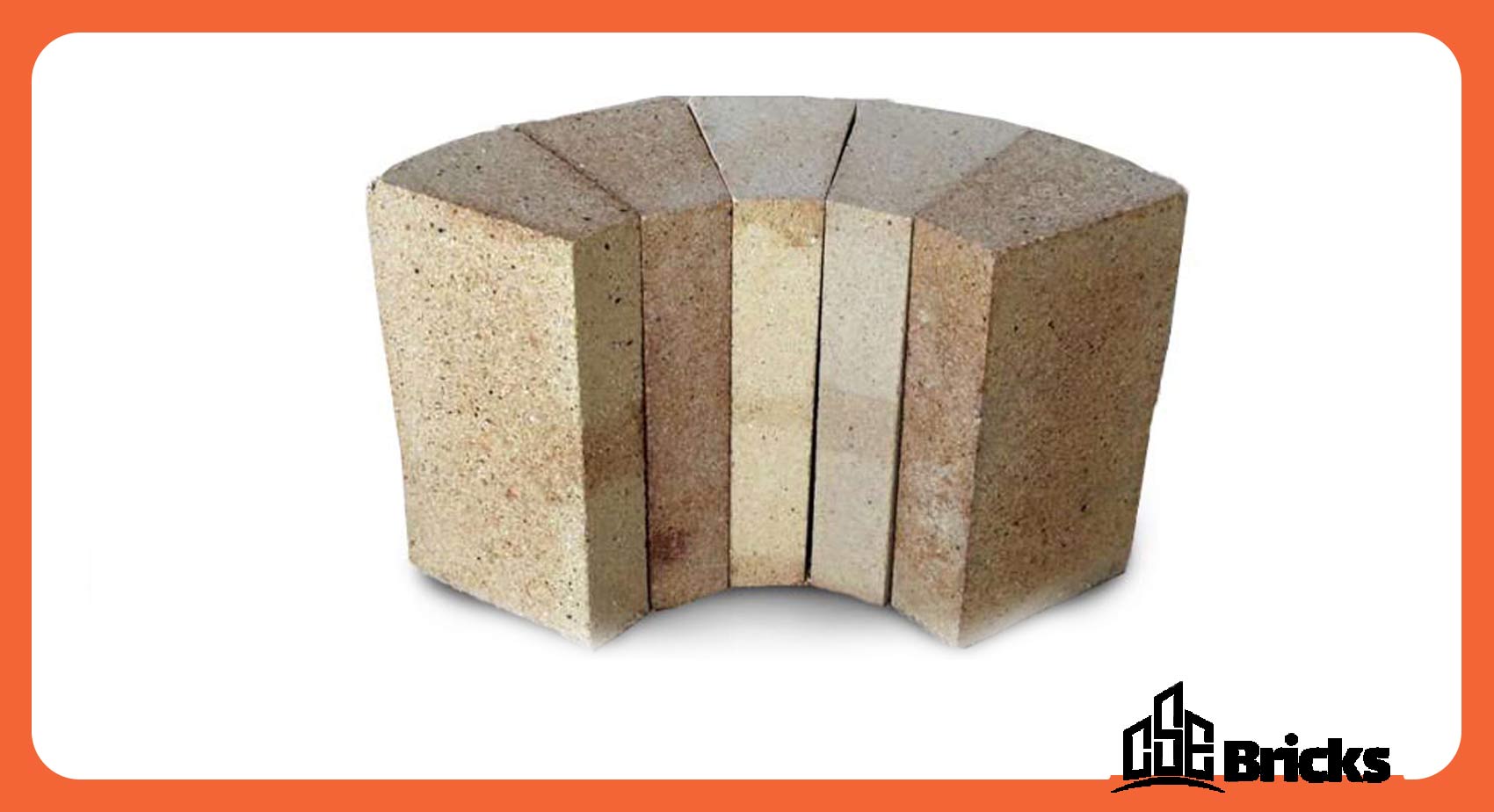

طوب النار (الطوب الحراري)

كما يدل اسمه، يتميز طوب النار بمقاومة عالية جدًا للحرارة، ويمكنه تحمّل درجات حرارة تتجاوز 1000 درجة مئوية بسهولة. تُعد مادتا السيليكا والألومينا من المكوّنات الرئيسية المستخدمة في تصنيع طوب النار، وتعود النقاط السوداء الظاهرة في هذا الطوب إلى وجود السيليكا. يتوفر طوب النار بألوان وأحجام متعددة مثل: 32 × 7 × 2.5 سم، 20 × 5.5 × 2.5 سم، 26 × 5.5 × 2.5 سم، 20 × 20 × 2.7 سم، 20 × 10 × 2.7 سم، 20 × 10 × 5.5 سم، 40 × 8 × 2.5 سم، و70 × 12 × 3 سم. يتراوح وزن طوب النار بين 2 و2.5 كغ. ويُستخدم هذا النوع من الطوب في تبليط الأرضيات، والواجهات الخارجية للمباني، والمدافئ، والأفران، وغيرها.

-

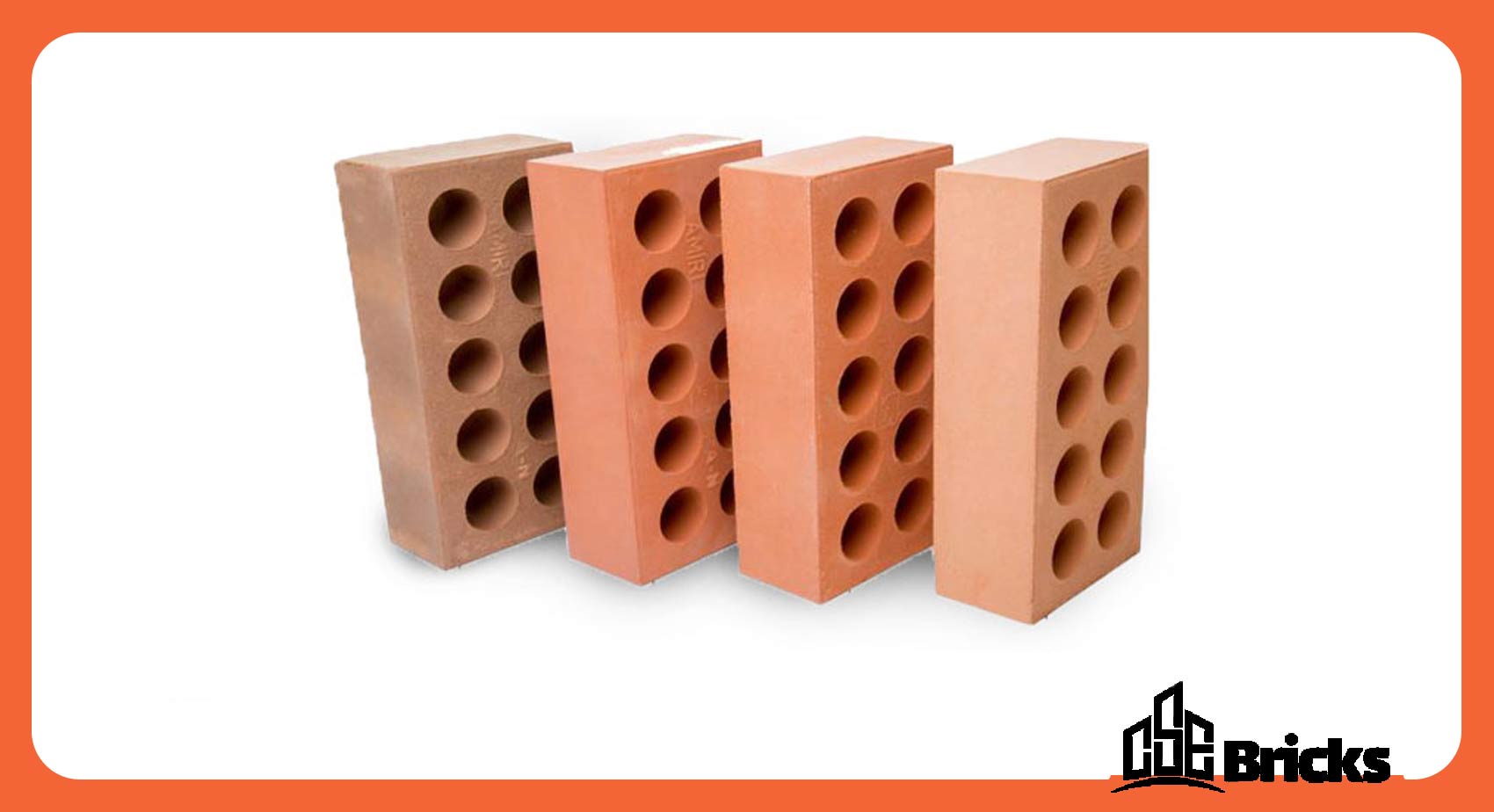

طوب لِفتون (Lefton Brick)

قد تعرف طوب لفتون بأسماء أخرى مثل الطوب ذو العشر فتحات أو الطوب المثقّب. وقد سُمّي بهذا الاسم لأنه صُنِع لأول مرة في قرية لِفتون بمحافظة أصفهان، ثم انتشر لاحقًا إلى مناطق أخرى من البلاد. المواد الخام الرئيسية المستخدمة في تصنيعه هي الطين أو الصخر الطفلي. تبلغ أبعاد طوب لفتون 20 × 10 × 5 سم، ويتوفر في الأسواق بألوان الأصفر والأحمر والخوخي. يبلغ وزن كل طوبة حوالي 800 غرام. ويُستخدم طوب لفتون في بناء المستودعات، وواجهات المباني، وترميم الأبنية القديمة، والجدران الحاملة للضغط.

-

الطوب المزجج

الطوب المزجج هو نوع من الطوب يشبه الطوب العادي، إلا أن الفرق يكمن في تغطيته بطبقة زجاجية (تزجيج). يتكوّن هذا التزجيج من مزيج من الطين وأكسيد الألومنيوم، مما يمنح الطوب سطحًا زجاجيًا لامعًا. تُطبَّق طبقة التزجيج على سطح واحد أو أكثر من الطوبة في المرحلة النهائية من عملية الإنتاج. وتُحدَّد الخصائص الشكلية للطوب المزجج، مثل اللون والحجم، وفقًا لطلب الزبون، ولا يوجد معيار ثابت لها. يُستخدم الطوب المزجج في تجميل الواجهات، وتصميم المساحات الداخلية للمباني، وأعمال التبليط والأرضيات، وتحديد أطراف الحدائق، وكذلك في المساجد والحسينيات.

-

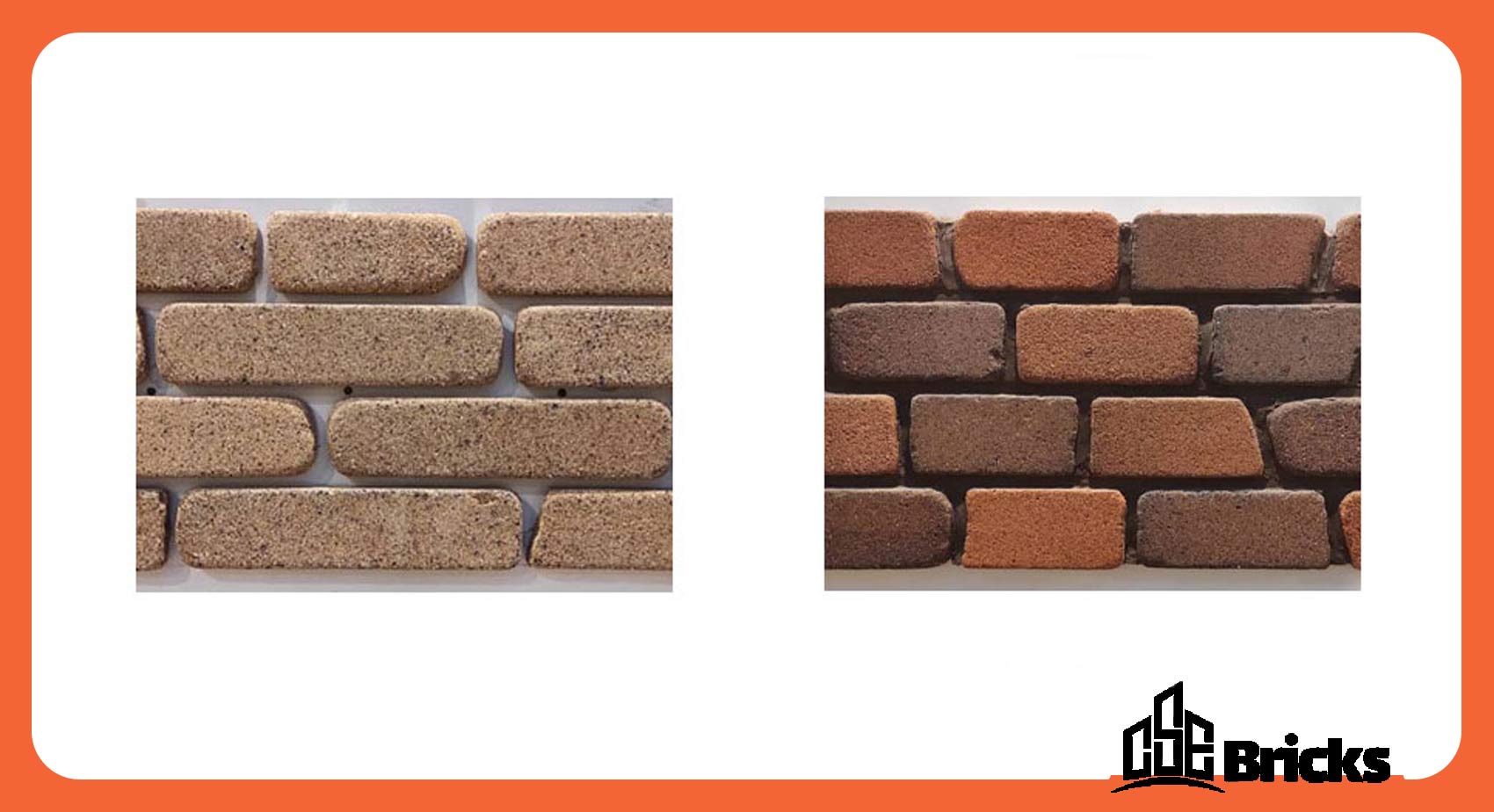

الطوب الزخرفي

يُعد الطوب الزخرفي نوعًا آخر من الطوب، وقد يُعرف أيضًا بأسماء مثل الطوب العتيق أو الطوب الهولندي. يحتوي الطوب العتيق في تركيبه على مواد بوليمرية ونانوية، تمنع نمو الفطريات والبكتيريا على سطح الطوب. كما يتميز بمقاومة حرارية ممتازة وتنوّع واسع في الألوان. ومن أهم الخصائص التي تجعل هذا النوع عمليًا: خفة وزنه، ومتانته العالية، وطول عمره الافتراضي. بالإضافة إلى ذلك، يتمتع الطوب الزخرفي بمقاومة فيزيائية جيدة جدًا، مما يجعله أقل عرضة للتلف تحت مختلف الظروف الجوية، كما أن انخفاض نفاذيته يجعله يعمل كعازل فعال.

-

طوب الجير الرملي

المادة الرئيسية المستخدمة في إنتاج طوب الجير الرملي هي سيليكات الكالسيوم، ويُستخدم هذا النوع من الطوب في بناء الأساسات. ومن أبرز خصائصه الفريدة مقاومته العالية للضغط، مما يمنحه قدرة كبيرة على تحمّل الأحمال، ولذلك يُعد مناسبًا لبناء الجدران الحاملة والجدران الساندة. وفي أثناء إنتاج هذا الطوب يمكن استخدام الأصباغ للحصول على طوب جميل ومتعدد الألوان. يتميز طوب الجير الرملي بمتانته العالية، كما أن شكله وأبعاده تسهّل عملية بناء الجدران بشكل كبير. إضافة إلى ذلك، فإن نسبة الهدر فيه قليلة جدًا. ويعمل هذا النوع من الطوب كعازل حراري ممتاز، حيث يمنع فقدان الحرارة في فصل الشتاء ودخولها في فصل الصيف.

-

الطوب المصنوع آليًا

يشبه الطوب المصنوع آليًا في شكله طوب كازاخ، ويُنتج باللونين الأحمر والأبيض. ويُستخدم هذا النوع من الطوب في واجهات المباني. ويكمن الفرق الرئيسي بين الطوب المضغوط والطوب المصنوع آليًا في نوع مادة الطين ووجود الثقوب داخل الطوبة، مما يجعلها أخف وزنًا ويوفّر التصاقًا أفضل مع المونة. إلا أن هذه الطوبات تكون أكثر هشاشة مقارنة بالطوب المضغوط. يتميز الطوب المصنوع آليًا بسطح أملس وحواف حادة. ولإنتاج الطوب المخطط باستخدام هذه الطريقة، يتم رص الطوب بشكل متناوب، مما يؤدي إلى ظهور خطوط لونية تعطي الواجهة مظهرًا جماليًا مميزًا. كما تُستخدم أكاسيد المعادن لإنتاج الطوب المصنوع آليًا الملوّن.

-

الطوب الخرساني

تتكوّن الطوبات الخرسانية بشكل أساسي من الأسمنت والرمل، ويتم إنتاجها بأحجام وأشكال مختلفة باستخدام ماكينات يدوية أو آلية لصناعة الطوب. ويُستخدم هذا النوع من الطوب بشكل رئيسي في أعمال الرصف، مثل الساحات، والحدائق، والأرصفة، وذلك بفضل تنوّع أشكاله وألوانه.

-

الطوب المقاوم للأحماض

إذا كنت تنوي بناء مكان يُحتمل فيه وجود مواد حمضية، فإن الخيار الأفضل في هذه الحالة هو استخدام الطوب المقاوم للأحماض. يتميز هذا النوع من الطوب بمقاومته العالية للمواد الحمضية المنصهرة، ولكن يجب الانتباه إلى أنه يتفاعل مع المواد القلوية. ويُعد طوب النار السيليسي مثالًا على الطوب المقاوم للأحماض.

-

طوب المغنيسيا الحراري

يُصنَّف طوب المغنيسيا الحراري ضمن الطوب الحراري القاعدي. وتُعد المادة الخام الرئيسية المستخدمة في إنتاج هذا النوع من الطوب هي أكسيد المغنيسيوم، والذي يتم الحصول عليه من الدولوميت.

-

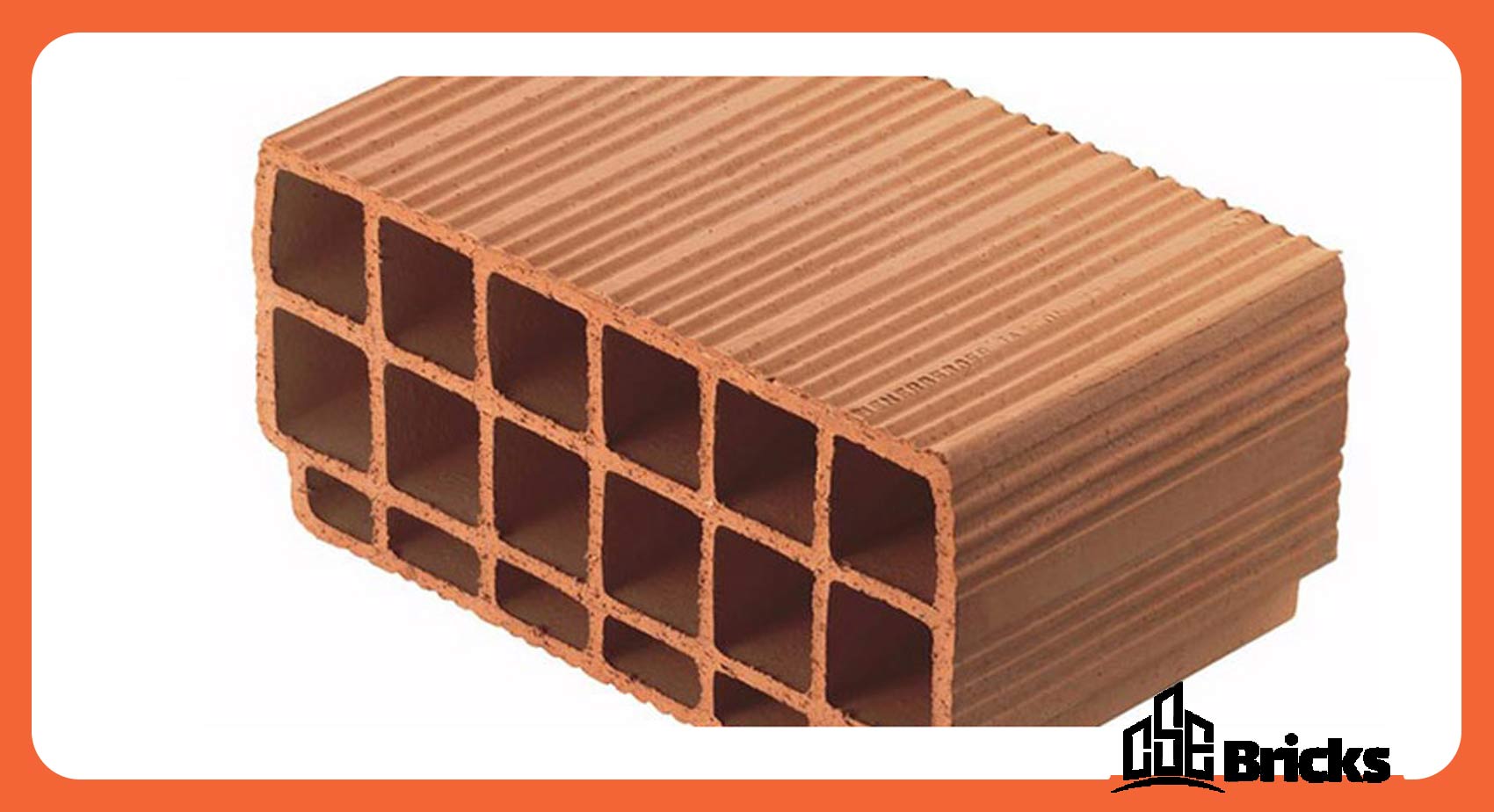

الطوب الطيني (طوب التقسيم)

يُعد الطوب الطيني، المعروف أيضًا بطوب التقسيم، من أكثر مواد البناء استخدامًا. ويُستعمل هذا النوع من الطوب في الواجهات الداخلية وأسقف المباني. يُنتج الطوب الطيني بأحجام مختلفة، ويتوفر في الأسواق باللونين الأحمر والأبيض. وتنقسم أنواعه إلى طوب أسقف، وطوب بلوك، وطوب مملوء بالفوم، وطوب جدران. كما تُصنَّف هذه الأنواع إلى ثلاث درجات من حيث الجودة: درجة أولى، ودرجة ثانية، ودرجة ثالثة.

-

الطوب المحروق

الطوب المحروق هو نوع آخر من الطوب يتمتع بقوة عالية جدًا وقدرة كبيرة على تحمّل درجات الحرارة المرتفعة للغاية. يتم إنتاج هذا الطوب عند درجات حرارة تتجاوز 1000 درجة مئوية، حيث يتعرّق الطين ويلتحم معًا، مما يؤدي إلى تكوين الطوبة. وتجعله قوته العالية خيارًا مناسبًا لبناء الأساسات. إضافةً إلى ذلك، يُستخدم الطوب المحروق في أماكن أخرى مثل أعمال الرصف، والمداخن، وأرضيات المراكز الصناعية، وكذلك في بعض المواقع الخاصة مثل شبكات الصرف الصحي والأنفاق.

الكلمة الأخيرة

كان الهدف من هذا المحتوى جمع وتقديم الأنواع المختلفة من الطوب وتطبيقاتها المتنوعة، وذلك لإرشادكم أيها القرّاء الكرام في اختيار الطوب المناسب لمشاريعكم الإنشائية.