المدونة

المواد الخام للطوب اللیغو

المواد الخام للطوب اللیغو

المواد الخام للطوب اللیغو

الطوب اللیغو، المعروف أيضًا باسم interlocking bricks، هو نوع من مواد البناء التي أصبحت شديدة الانتشار في الإنشاءات الحديثة، مما جذب اهتمام المصنّعين ورواد الأعمال. في هذا المقال، سنقوم بالتعريف وفحص المواد الخام للطوب اللیغو، والتي من المهم لكل من المصنّعين والمستهلكين معرفتها.

ما هو الطوب اللیغو؟

يُعد طوب الليغو يحتوي على بروزات وتجويفات تسمح له بالترابط معًا، ولهذا السبب أُطلق عليه اسم “interlocking”. إن تصنيع واستخدام هذا النوع من الطوب مربح لكل من المنتجين والمستخدمين. بالنسبة للمُصنّعين، فإن إنتاج هذا الطوب اقتصادي بسبب توافر المواد الخام ورخصها، إضافة إلى الطلب العالي عليه في سوق اليوم.

أما بالنسبة للبنّائين، فإن سهولة البناء وتقليل الحاجة للمواد والمونة يسهمان في تخفيض التكلفة. ولكن فوائد هذا الطوب للمستهلكين تتجاوز مسألة تقليل التكاليف. فعلى سبيل المثال، تجعل المواد الخام المستخدمة في الطوب اللیغو أكثر قوة من الطوب العادي، مما يمنحه مقاومة عالية للزلازل والضغط الثقيل. بالإضافة إلى ذلك، يعمل هذا الطوب كعازل حراري وصوتي. “اقرأ المزيد عن مزايا الطوب اللیغو الأخرى في المقالة مزايا الطوب اللیغو الأخرى في المقالة ذات الصلة.”

ما هي المواد الخام للطوب اللیغو؟

يمكن إنتاج الطوب اللیغو بتركيبات ونسب مختلفة، وهو ما يعد ميزة رائعة لهذا النوع الفريد من الطوب. يمكن أن تشمل المواد الخام للطوب اللیغو التربة الكلسية، الرمل، أنواع مختلفة من التربة، البيرلايت، الحبيبات المعدنية الناعمة والخشنة، كربونات الكالسيوم، وغيرها. فيما يلي نستعرض النسب القياسية العامة لمكوّنات الطوب اللیغو:

- التربة أو مخلفات المناجم: 70%

- بودرة الحجر: 20%

- الإسمنت: 10%

- بودرة التلوين

- ماء

التربة ومخلفات المناجم (المكوّنات الأساسية للطوب اللیغو)

تُعد التربة ومخلفات المناجم المواد الخام الأساسية للطوب اللیغو، والتي يمكن أن تشمل نفايات مناجم الرمل والحصى أو أنواعًا مختلفة من مناجم التربة. بالإضافة إلى ذلك، تُعد مخلفات مصانع قصّ الحجر والحجر الصناعي، ومخلفات البناء، ومخلفات مصانع إنتاج الطوب خيارات مناسبة لإنتاج الطوب اللیغو. ويمكن أن تتراوح نسبة هذه المواد ما بين 70% إلى 80% بحسب الحاجة.

-

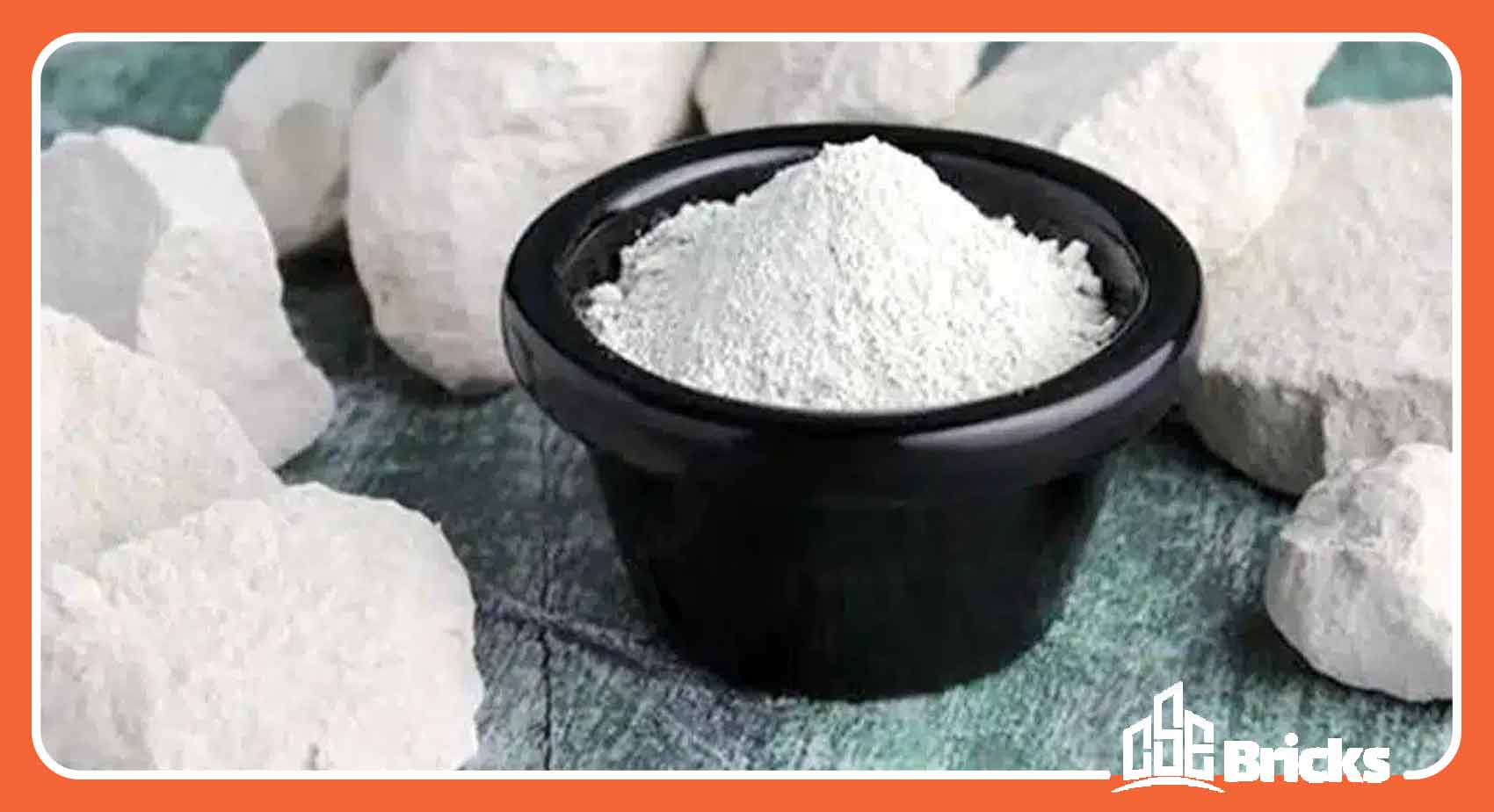

بودرة الحجر

تُعد بودرة الحجر إحدى المواد الخام المستخدمة في صناعة الطوب اللیغو، وهي تعمل على زيادة قوة ومتانة الطوب. يجب إضافة بودرة الحجر إلى الخليط بحسب نوع المخلفات المستخدمة في صناعة الطوب. فمثلًا، في حال استخدام مخلفات مصانع قصّ الحجر أو الحجر الصناعي، فلن تكون بحاجة إلى إضافة بودرة الحجر. أما إذا كنت تستخدم التربة الطينية أو مخلفات مناجم الرمل والحصى، فمن الأفضل إضافة بودرة الحجر بنسبة 20% لزيادة قوة الطوب.

-

الإسمنت

يُعد الإسمنت من المواد الأساسية المستخدمة في إنتاج الطوب اللیغو، حيث يُخلط مع باقي المواد بنسبة تتراوح بين 10% إلى 20% حسب نوع الطوب المنتج. فعلى سبيل المثال، لإنتاج بلاط الأرضيات، يُفضَّل استخدام نسبة أعلى من الإسمنت.

-

بودرة التلوين

إذا كنت ترغب في إنتاج طوب ملوّن، فيمكنك إضافة بودرة التلوين. تُستخدم الطوب المصنوع مع بودرة التلوين في واجهات المباني وفي أعمال الرصف. ويمكن أن تكون بودرة التلوين مكوّنة من أصباغ كيميائية أو معدنية. (يُنصح بالرجوع إلى المقالة ذات الصلة للتعرّف على أنواع طوب الواجهات.)

-

ماء

يجب إضافة الماء إلى المواد المذكورة أعلاه بالكمية اللازمة لعملية الخلط.

الكلمة الأخيرة

كما علمنا، فإن المواد الخام للطوب اللیغو تُستخرج من النفايات أو المخلفات التي قد تُسبب ضررًا للبيئة إذا تُركت في الطبيعة. لذلك، فإن استخدام المصنّعين لهذه المواد وتحويلها إلى مواد بناء مقاومة للزلازل يُعد خدمة كبيرة للبيئة.