المدونة

استخدام طوب الليغو – المزايا والعيوب

استخدام طوب الليغو – المزايا والعيوب

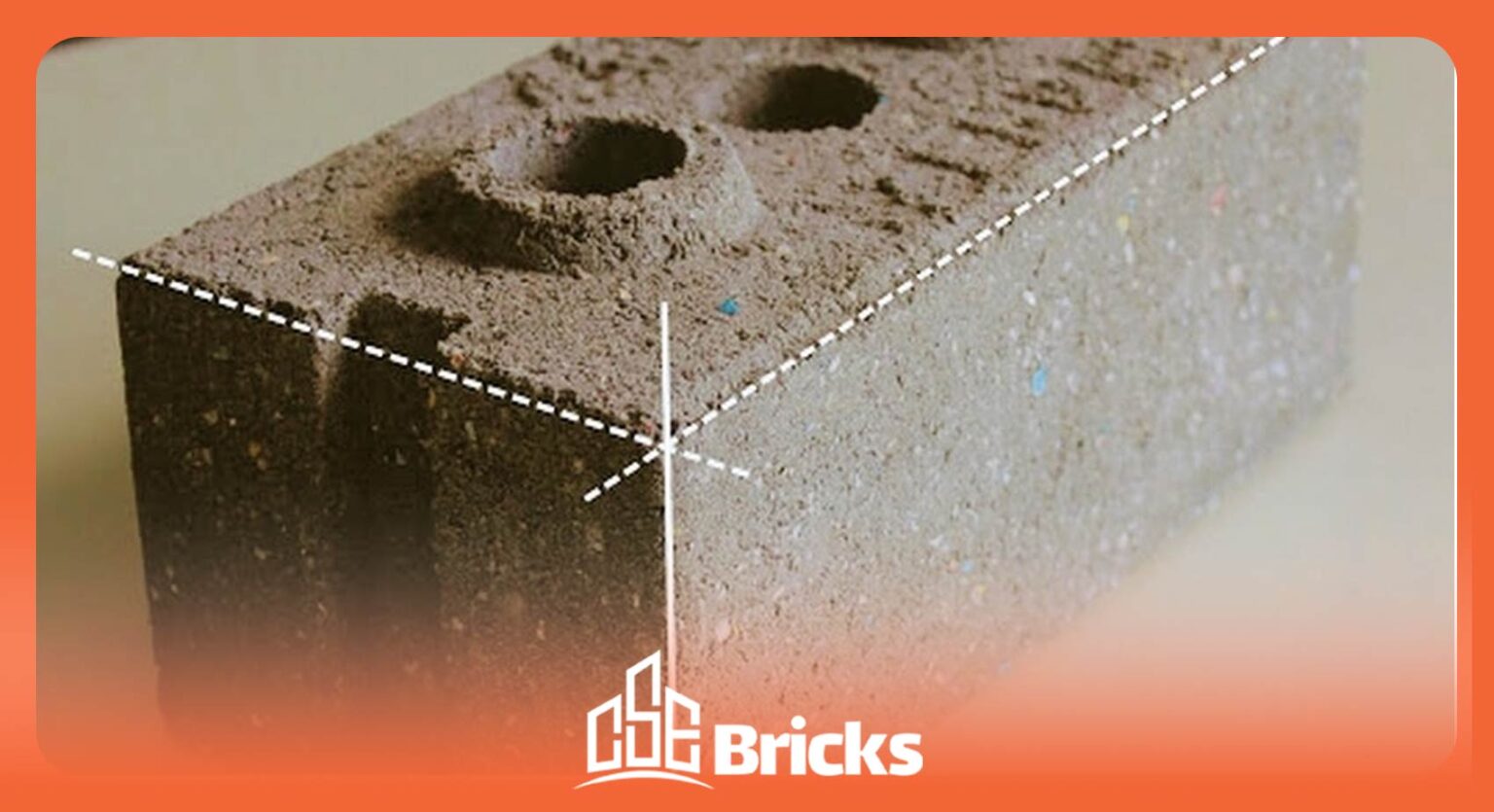

طوب الليغو، المعروف عالميًا باسم الكتل الترابية المستقرة المضغوطة (CSEB)، هو نوع مبتكر وحديث نسبيًا من مواد البناء. إن فوائده العملية والجمالية جعلته أكثر شيوعًا في البناء المعاصر. في هذا المقال، سوف نستكشف استخدامات طوب الليغو، بالإضافة إلى مزاياه وعيوبه.

استخدامات طوب الليغو

من حيث المواد الخام، فإن طوب الليغو عبارة عن مزيج من العناصر الطبيعية والموارد المتوفرة بكثرة. إن مزايا طوب الليغو، مثل التنوع في النماذج والألوان المنتجة، إلى جانب معاملات الأمان العالية، جعلته أكثر جاذبية وشعبية مقارنة بمواد البناء الأخرى.

إحدى الأسباب الرئيسية التي جعلت طوب الليغو عمليًا للغاية هي سهولة وسرعة تركيبه، وقوة تحمله العالية للضغط، وعزله الحراري، ومظهره الجميل، وفعاليته من حيث التكلفة. يتم بناء الجدران باستخدام هذا الطوب في صف واحد مع مادة لاصقة قوية. فيما يلي بعض استخدامات طوب الليغو في بناء الجدران:

- المسابح

- الشوايات

- العرائش

- المناطق، القاعات، الورش، الفلل، إلخ.

- الجدران، الأعمدة، الهياكل الحاملة، الحدائق، إلخ.

ما هي مزايا طوب الليغو؟

-

استخدام طوب الليغو في خفض التكاليف

من خلال استخدام طوب الليغو، يتم تحقيق واحد من أهم العوامل في البناء، وهو خفض التكلفة النهائية للمنتج المُنتَج دون التأثير على الجودة. وهذا سبب قوي لاستخدام طوب الليغو في بناء مختلف الجدران والهياكل.

-

Reducing Transportation Costs

The selection of raw materials for producing interlocking bricks is not limited. According to the standard formula, 70% of the raw materials used for producing interlocking bricks and blocks consist of soil, which can include clay, ordinary soil, garden soil, or even sand washing mine waste. Reducing transportation costs is one of the most important advantages of puzzle bricks, making it a significant advantage for brick manufacturers, especially mine owners. (In this regard, we recommend studying mine waste management.)

-

Energy Consumption Reduction

One of the advantages of bricks produced with an interlocking brick machine without a kiln is the reduction in time costs, fuel consumption, and air pollution. Buildings constructed with these thermal insulating bricks consume less energy during cold seasons due to their ability to retain heat. Therefore, given the excessive global consumption of fuel and energy, interlocking bricks in construction can contribute to more efficient energy use.

-

Reduction in Labor Costs

Another benefit of interlocking bricks is the increased speed of construction. Since wall construction with interlocking bricks is done using adhesive, the construction process becomes faster. Consequently, this reduces the labor costs paid to workers, making it a favored option for employers.

-

Reduction in Material Purchase Costs

Using interlocking bricks is also effective in reducing material purchase costs. Constructing and wall-building with other types of bricks involves the cost of purchasing materials and intermediate mortars such as cement, concrete, steel, and more. However, wall-building with interlocking bricks is cost-effective for both the manufacturer and the consumer, as there is no need to purchase intermediate materials. Additionally, interlocking bricks are connected using adhesive, and one package of adhesive is sufficient for one square meter, making it very cost-efficient.

-

Reduction in Finishing and Plaster Costs

Since the design of interlocking bricks features interlocking male and female ends and has two-sided facing, it eliminates the need for jointing, finishing, and ultimately plastering costs. By using this design, the building process becomes easier and total costs are lowered.

-

Reduction in Façade Costs

Interlocking bricks and blocks are produced in various sizes and a wide range of colors, making them highly useful for your construction projects with their quick and easy installation. Additionally, constructing walls with these environmentally friendly bricks can be completed in a short time, which reduces the costs associated with painting or applying a façade to the building. This is another advantage that makes interlocking bricks appealing.

-

Reduction in Demolition or Wall Covering Costs

Another advantage of interlocking bricks is the presence of holes and grooves, which help in wall construction by reducing the costs of demolition or re-covering the wall. Thanks to this optimized design, you can easily complete plumbing and building installations with minimal waste.

As a result, whether you are a manufacturer of interlocking bricks using an interlocking brick machine or you wish to use this product in your construction projects, you will benefit economically in both cases.

-

Earthquake Resistance

Given the importance of safeguarding human lives and adhering to building regulations aimed at increasing the safety of structures under construction, using interlocking bricks is an ideal choice due to their compressive strength, which has been tested at 30MPa. Additionally, the unique design of these bricks allows for vertical or horizontal reinforcement with rebar through the holes in the green bricks, making the building more robust and secure against potential earthquake pressures and vibrations.

-

العزل الحراري

Interlocking bricks and blocks produced with an interlocking brick machine are thermal insulators and fire-resistant. In fact, fire tests conducted on interlocking bricks have shown that their heat transfer is nearly zero. This is one of the advantages of interlocking bricks, as they not only protect your life during fire incidents but also prevent heat loss during winter, conserving energy.

-

Sound Insulation

Due to the design featuring two holes between the interlocking bricks, a double-layer effect is created, which makes them sound insulators. This characteristic helps in reducing noise transmission, adding another advantage to the use of interlocking bricks in construction.

-

Application of interlocking Bricks in Fast and Simple Execution

Another application of interlocking bricks in wall construction is that they do not require specialized labor. The arrangement of the bricks is done using adhesive without the need for jointing or special skills, and they dry quickly. This allows you to complete your construction easily and cleanly. (Read more about interlocking brick adhesive in the related article.)

-

Variety of Molds and Colors

Interlocking bricks come in various molds such as grooved bricks, partitions, floor tiles, and more. They are available in a range of colors, including mineral colors (red and brown) and chemical colors (white, blue, yellow, etc.), which can match your preferences and enhance the beauty and appeal of your structure. This variety of molds and colors is one of the advantages of interlocking bricks.

-

No Color Change and High Durability

The production of interlocking bricks involves using readily available raw materials such as clay and stone dust. During this process, the desired color powder is mixed with these materials, and the mixture is then compressed by the interlocking brick machine to create the final product. As a result, the produced bricks do not change color over time. It is also worth mentioning that waterproof interlocking bricks have a longer lifespan.

-

eco-friendly Bricks and Environmental Protection

Interlocking bricks are pressed with high pressure by an interlocking brick machine without the need for a kiln. This process prevents the release of carbon dioxide gas and air pollution, thereby protecting the environment. This is one of the globally popular advantages of interlocking bricks. For more information on this topic, you can read the article “Types of Tests and Standards for interlocking Bricks” on interlocking Brick.com.

-

No Wall Demolition for Pipe and Installation Passage

The engineering design of interlocking bricks, due to their holes, allows for the passage of rebar, pipes, and building installations during construction. This feature, combined with dry stacking, eliminates the need for wall demolition when installing these elements.

Disadvantages of interlocking Bricks

- One of the disadvantages of interlocking bricks is that their unique and attractive designs may not align with the tastes of those who prefer classic and traditional styles. This can be a potential drawback for some individuals when considering interlocking bricks for their construction projects.

- The weight of a single piece of interlocking brick is high, which can make transportation and installation difficult.One drawback associated with interlocking bricks is this. However, due to the absence of mortar between the rows, wall construction with this type of brick is lighter in large areas compared to other bricks.

- Due to the gaps between the pieces, interlocking bricks are more sensitive to moisture. Therefore, this can be considered one of the disadvantages of interlocking bricks.

- Cleaning the surface of bricks is not easy.

- Due to the weight of interlocking bricks and building regulations, it is recommended to use these bricks for construction up to a maximum of two stories. This is considered one of the disadvantages of interlocking bricks.

How to Reduce the Disadvantages of interlocking Bricks?

Appearance of interlocking Bricks:

Even though interlocking bricks feature a neat, attractive design and are available in multiple colors, if their appearance does not suit your preference, their smooth and even surface allows you to easily apply your desired façade.

Weight of interlocking Bricks and Blocks:

The weight of individual interlocking bricks and blocks is higher compared to ordinary bricks. However, it is interesting to note that the weight of a one-square-meter wall made of interlocking bricks is much less than that of regular walls. This is because significantly less mortar is used in between, and a single-row wall is constructed.

Water Absorption of interlocking Bricks:

Interlocking bricks may absorb moisture; however, it is important to note that these bricks have undergone water absorption tests and do not get damaged by moisture.

Construction with interlocking Blocks:

The weight of interlocking blocks and interlocking bricks is high, which is why construction beyond two stories with them is not recommended. However, if you use the lightweight type of brick (which uses materials such as Hebel and perlite), you can build more than two stories with it.

Final Words

Considering the application of interlocking bricks and their high profitability in both production and consumption, you have the opportunity to produce and sell these bricks in your region, achieving at least a 30% reduction in traditional construction costs. Additionally, the buildings you construct will be earthquake-resistant, which will make them more popular among people.

By starting this business and producing interlocking bricks with an interlocking brick machine, you will become an entrepreneur who, through beneficial work, has employed between 3 to 7 of your fellow citizens.

You can post your comments or questions related to the interlocking brick machine or interlocking bricks in the article’s comment section. We will respond to your questions as soon as possible.