Blog

?What is the difference between interlocking blocks and concrete blocks

?What is the difference between interlocking blocks and concrete blocks

?What are Bricks and Blocks

-

Bricks:

Bricks are one of the most important building materials used for constructing walls, pavements, and other structural elements. In ancient times, the term “brick” referred to a unit made of clay. .Nowadays, it refers to rectangular materials made from shale, clay, calcium silicate, concrete, or other soil materials. Bricks are typically bonded together using mortar or special adhesives

-

Blocks:

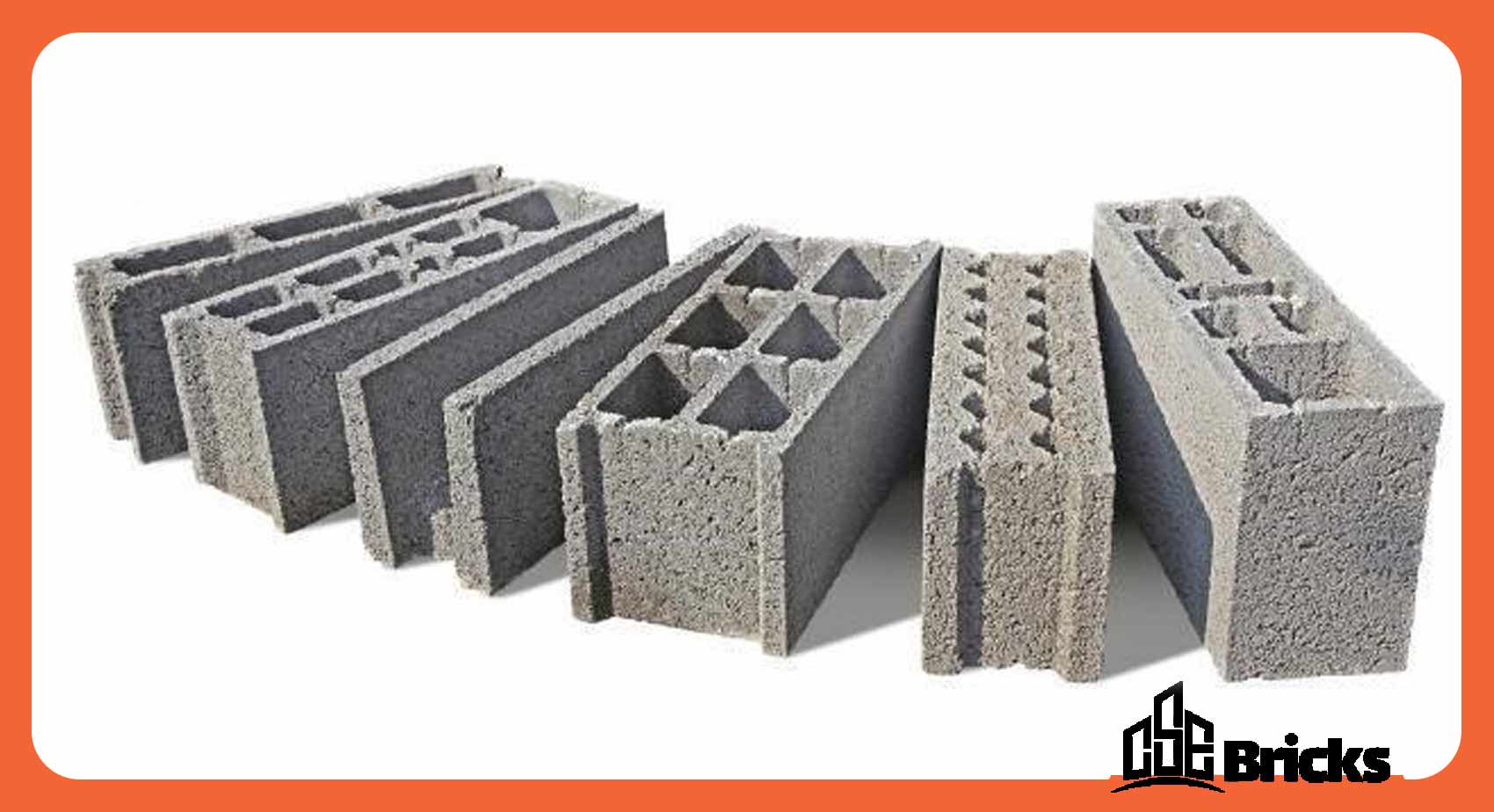

Blocks are generally larger than bricks. They are rectangular units made from various materials depending on the required strength and weight

Three Advantages of Interlocking Blocks

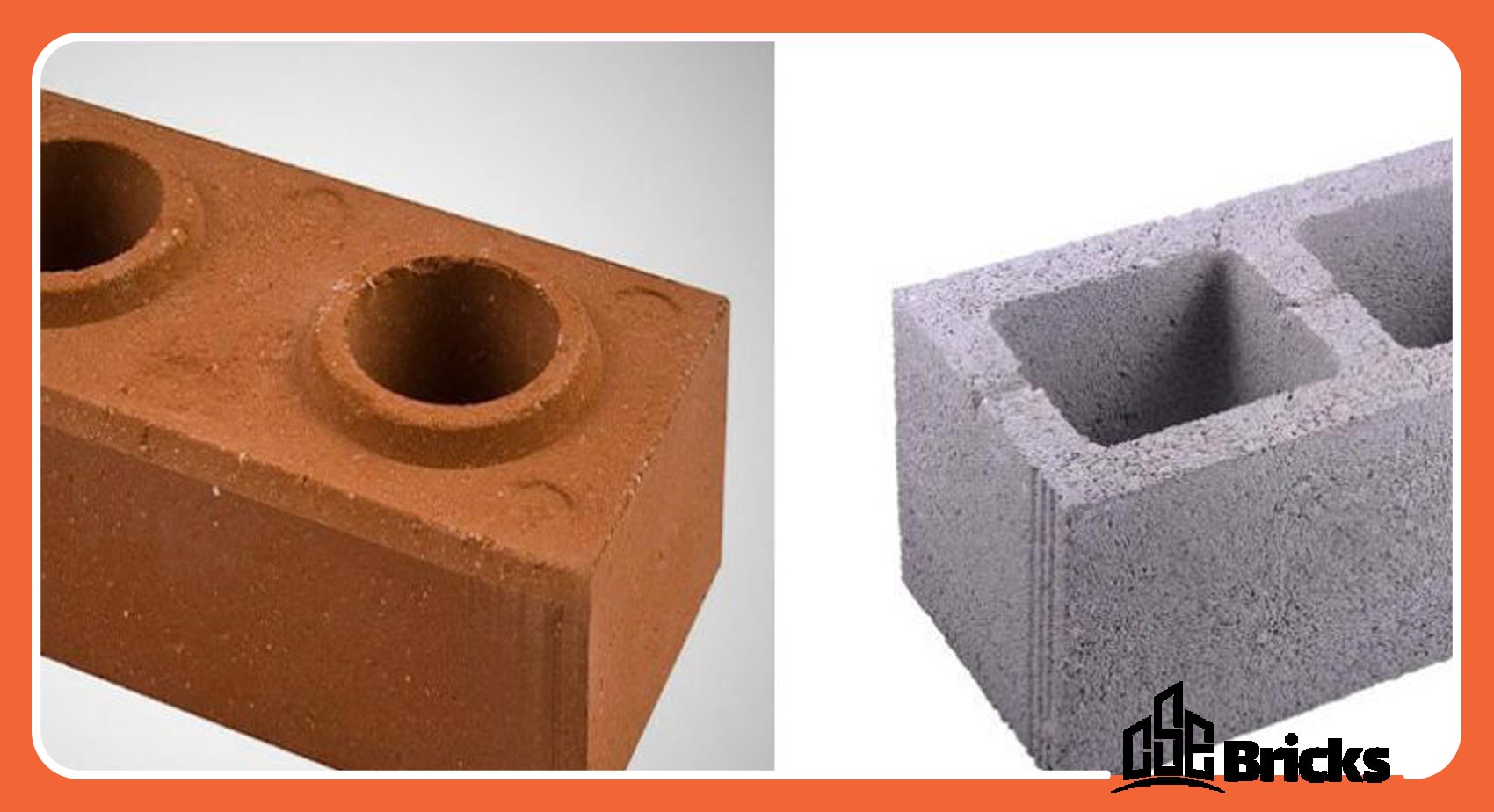

Bricks and interlocking blocks are building materials used in construction today. They come in various colors and designs. Due to their similarity to and the way they are assembled like Lego, they are called interlocking or Lego blocks and bricks. The presence of holes in the body of interlocking blocks and bricks allows for the easy passage of building equipment through these holes, eliminating the need for wall demolition by architects or builders. Additionally, interlocking blocks and bricks provide sound and thermal insulation, which results in energy and cost savings.

With the advancement of technology, interlocking blocks and bricks are now used in construction to reduce energy consumption and costs, and to speed up building processes. Let’s compare traditional bricks and blocks with interlocking (earth or cse) bricks and blocks. Stay tuned! (For more information, refer to the article on the application and advantages and disadvantages of interlocking bricks.)

5 Differences Between Interlocking Blocks and Concrete Blocks

The most significant differences between traditional materials and interlocking blocks (CSEB) and bricks can be summarized in terms of size, raw materials, shape, color, and weight. In fact, interlocking blocks and bricks are generally larger and heavier compared to traditional blocks and bricks.

Weight

The weight of a regular brick is usually between 2 to 2.5 kg, and the weight of a standard block ranges from 12 to 14 kg. In contrast, the weight of an interlocking brick is between 3 to 3.3 kg, and an interlocking block weighs between 7 to 8 kg. At first glance, interlocking bricks may seem heavier than compressed bricks, but you need to consider that in wall construction with interlocking blocks and bricks, mortar is not used. Instead, the overall weight of the wall is much less compared to a wall constructed with cement blocks and mortar. This is because in wall construction with interlocking bricks, mortar is eliminated, and brick adhesive is used to connect the bricks.

Appearance

-

Compressed Bricks:

Also known as rough bricks, these have a uniform appearance with a rough surface. In contrast, machine-made models have holes and a smoother surface

-

Blocks:

Blocks are available as hollow or solid and are used in various construction applications, such as interior and exterior walls, load-bearing and non-load-bearing structures, partition walls, beam and block ceilings, and other structural sections.

-

Interlocking Blocks and Bricks:

These have a similar shape to each other and differ only in dimensions. Interlocking blocks and bricks, as shown in the image below, have two holes for the passage of building equipment and rebar.

Raw Materials

-

Bricks:

The main body of bricks is composed of minerals, natural clay, including kaolin and shale. Small amounts of manganese, barium, and other additives are combined with the clay to produce bricks.

-

Blocks:

In general, the materials for lightweight blocks include hydraulic cement, light mineral and organic aggregates (natural or synthetic), water, and, if necessary, additives

Recycled materials from building demolition, waste from mines containing soil substances (such as sand and gravel mines, refractory clay mines, silicon mines, pumice and perlite mines, crusher mines, and calcium carbonate mines), as well as waste from stone cutting factories, brickmaking factories (kiln bricks), artificial stone factories, and ceramics factories can be used as raw materials for interlocking bricks and blocks.

Color

Another difference between traditional bricks and blocks compared to interlocking bricks and blocks lies in their color. During the production of interlocking bricks and blocks, manufacturers can add their desired color to the raw materials, producing colored interlocking bricks and blocks. This feature is one of the advantages and distinctions of interlocking bricks and blocks over compressed bricks and traditional blocks.

Based on the above review and information, it can be concluded that construction with interlocking bricks and blocks is advantageous for builders in all aspects, significantly optimizing time and cost.