Blog

Disadvantages of Cement Blocks

Disadvantages of Cement Blocks

Disadvantages of Cement Blocks You Might Not Know:

Among the most commonly used materials in construction are cement blocks. Most contractors use these blocks for their construction projects, but they are not very aware of the disadvantages of cement blocks. In this article, we will first provide a brief introduction to these building materials, then examine their disadvantages, and finally compare them with interlocking bricks, which are produced using the latest methods.

?What is a Cement Block

A cement block, also known as a concrete block, is a pre-fabricated piece of concrete that is made using a lower grade of cement. These blocks are commonly used in the construction of buildings, walls, and ceilings. To connect cement blocks together, similar to bricks, a mortar mix of sand, cement, and water is used. Cement blocks are produced in various sizes and weights to meet different construction needs.

:Components of Cement Blocks

- Types of Portland cement

- Fine aggregate sand

- Coarse sand

- Types of lightweight aggregates (artificial and mineral)

- Water

- Permissible additives

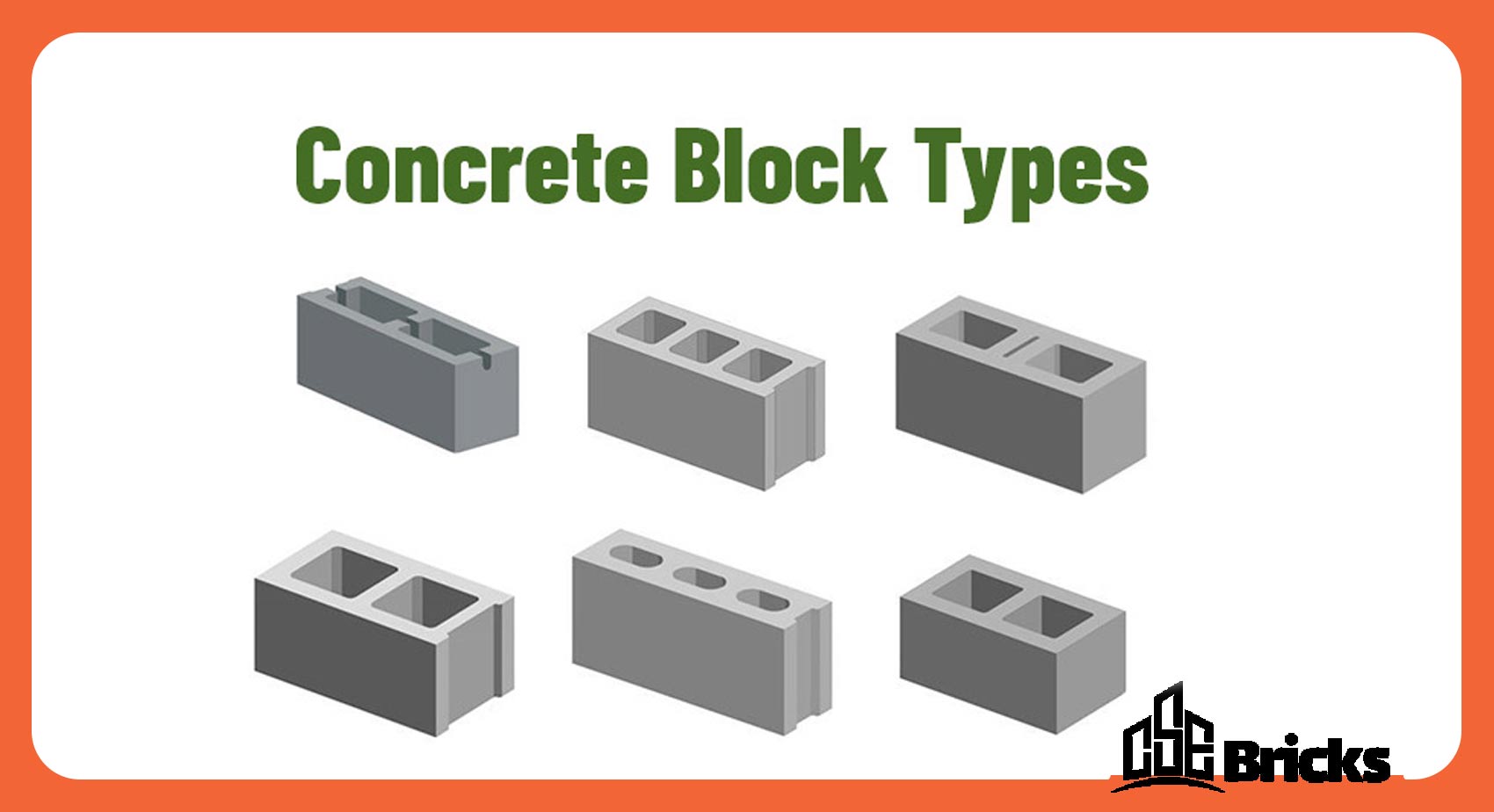

Types of Cement Blocks

Cement blocks are generally categorized into three groups:

• Lightweight Cement Blocks:

Lightweight cement blocks refer to blocks that use fillers such as mineral pumice, lightweight industrial materials, and air bubbles. These types of cement blocks are mostly used in beam-block ceilings. The weight of these blocks ranges between 500 to 700 kilograms per cubic meter.

• Semi-Lightweight Cement Blocks:

Semi-lightweight cement blocks are similar to lightweight cement blocks and are often categorized together. This type of cement block typically weighs between 700 to 1000 kilograms per cubic meter.

• Heavyweight Cement Blocks:

The fillers used in the concrete of heavyweight cement blocks are sand and gravel. Due to the use of concrete in these blocks, it is obvious that they have a high weight, which is considered one of the disadvantages of cement blocks. Heavyweight blocks are mostly used in landscaping and wall construction.

Factors Affecting the Price of Cement Blocks

Overall, the final cost of cement blocks is related to three main factors:

- Cement

- Sand

- Water

In fact, the cost of these three main components directly affects the price of cement blocks.

?What are the Disadvantages of Cement Blocks

Cement blocks undoubtedly have many significant and notable advantages that make them highly valuable in construction. However, they also have some disadvantages that we will examine below:

-

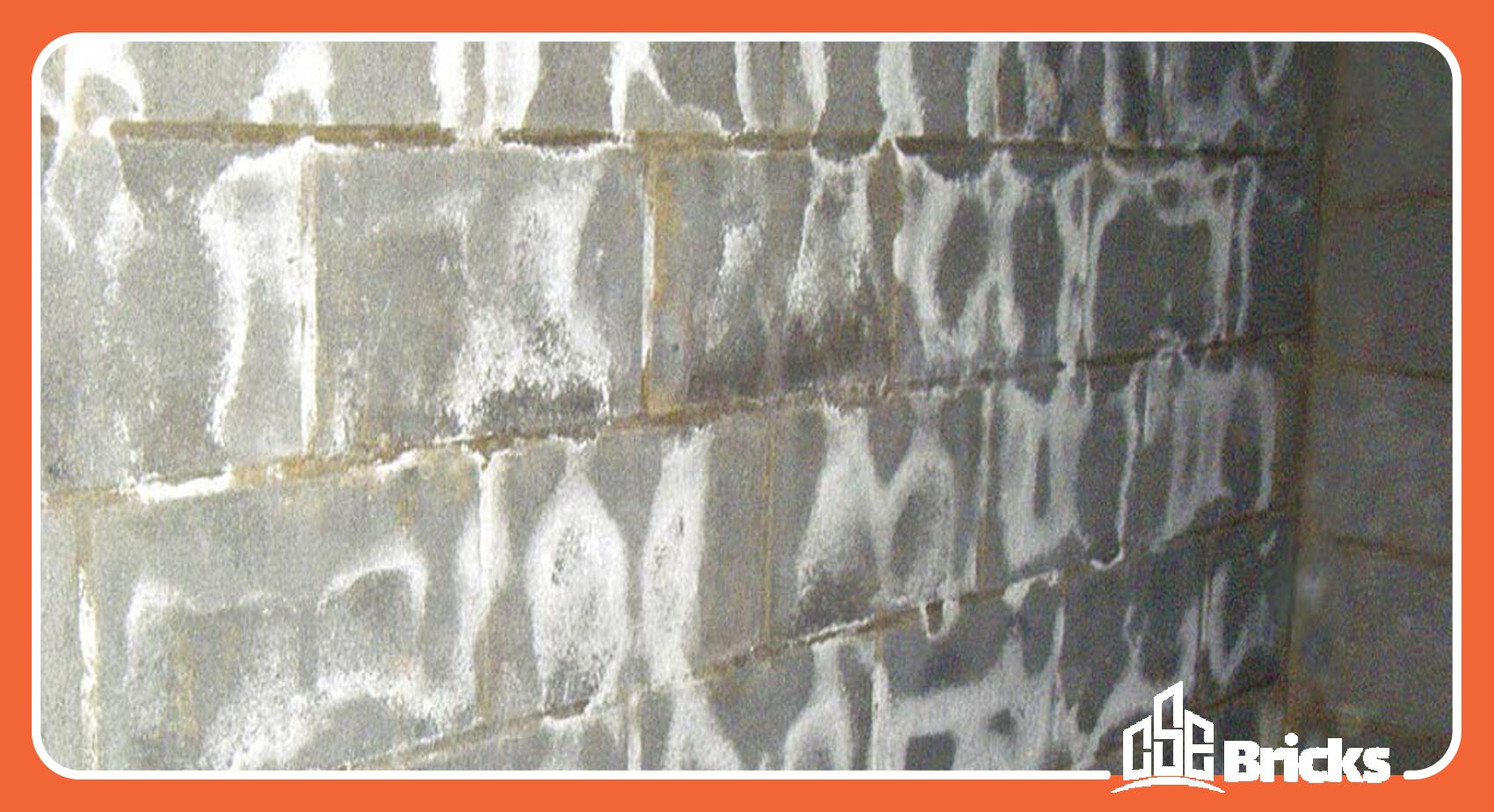

Unstable Against Moisture:

Cement blocks have low resistance to moisture and dampness. Therefore, if they are used in areas with high humidity, there is a possibility of damage and cracking.

-

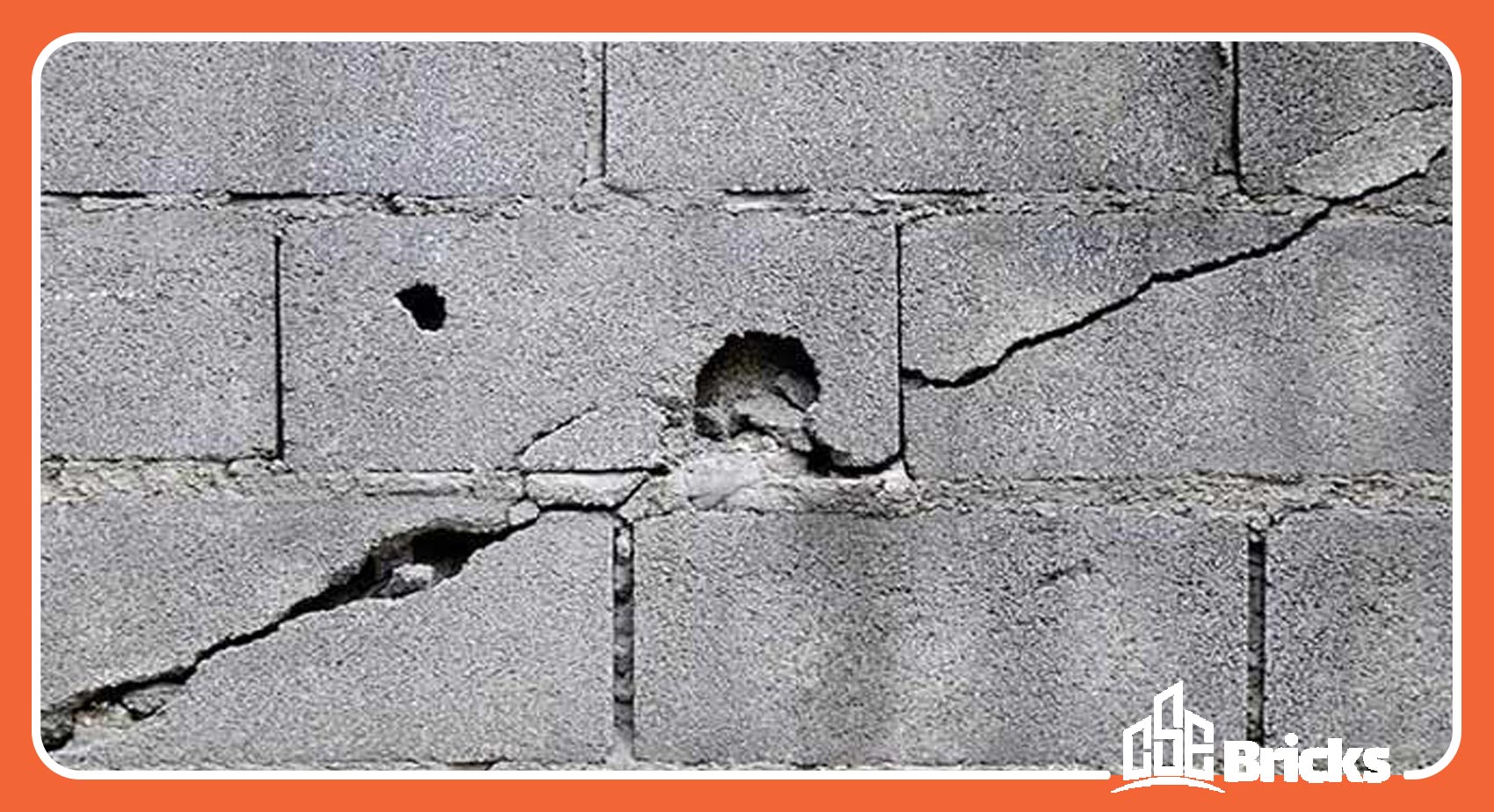

Low Strength at Heights Over 3 Meters:

Another disadvantage of cement blocks is their low strength. Typically, when cement blocks are used in wall construction and exceed a height of 3 meters, their resistance decreases. It is worth noting that this issue is only applicable to perimeter wall construction and not to building construction.

-

Damage During Transportation:

One of the most notable disadvantages of cement blocks is the breakage and damage that occurs during transportation. However, breakage during transportation can happen to any construction material.

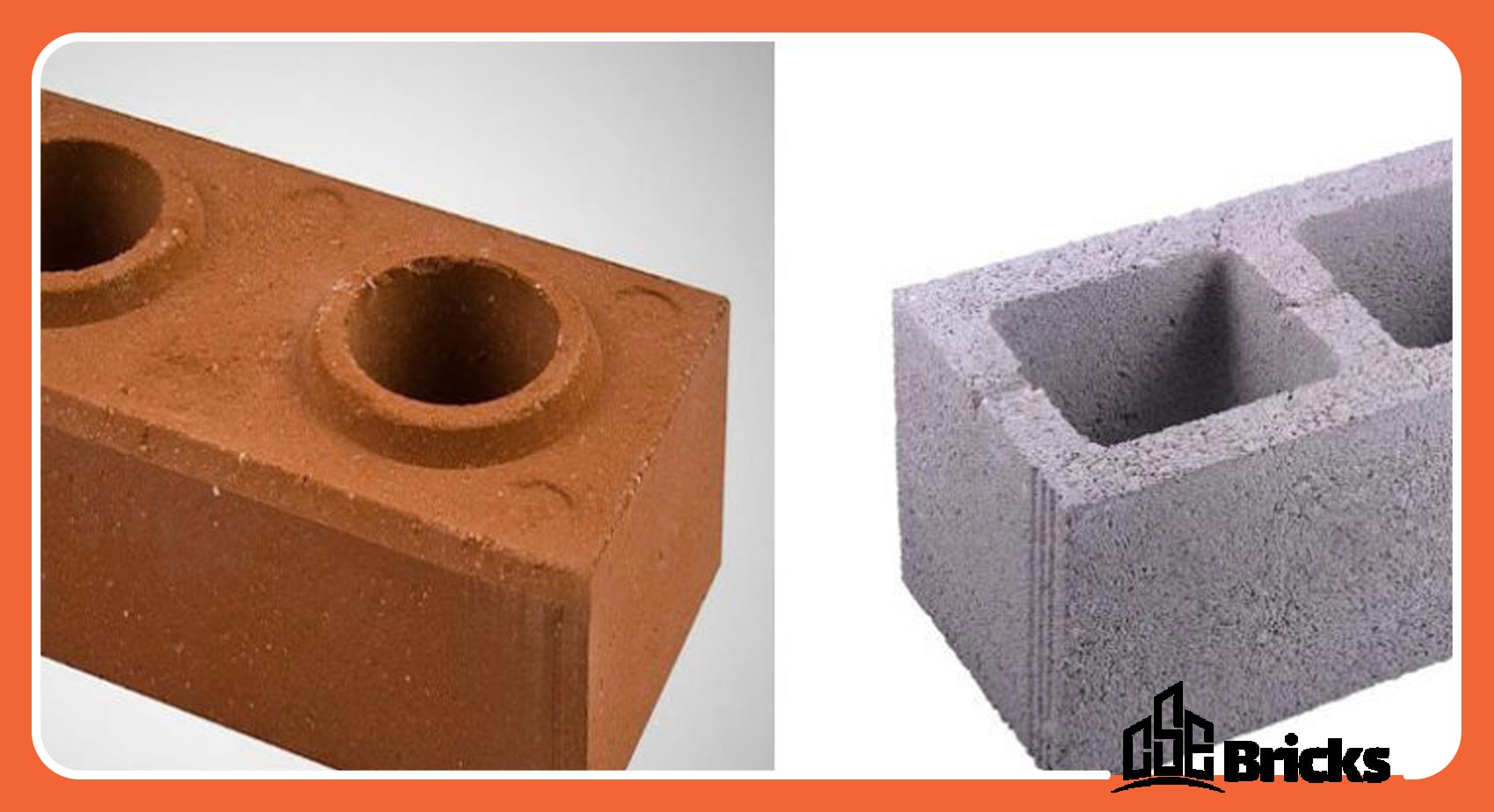

Comparison of Cement Blocks with interlocking Bricks

Interlocking bricks, which are made by compressing soil and using modern techniques, are used today all around the world, including in our country. Given the outstanding advantages of these bricks, the discussion has arisen whether it is better to use interlocking bricks or cement blocks. Therefore, we will compare cement blocks with interlocking bricks below.

Comparison of Cement Blocks with interlocking Bricks

- Thermal Insulation: inter locking bricks have better fire resistance compared to cement blocks.

- Strength: interlocking bricks have much greater strength compared to cement blocks because the compacted soil materials make them dense, leaving little space between particles, preventing fire from penetrating and spreading combustion.

- Recyclability: Although cement blocks are recyclable, bricks have the upper hand in this regard. Bricks, being made of soil, can more easily return to their original state.

- Budget: If you have a limited budget, cement blocks are more cost-effective. However, you should consider the disadvantages of cement blocks, and if they are not a problem, then choose this type of block.

- Maintenance: interlocking bricks rarely get damaged, so you won’t need to repair brick walls often. In contrast, block structures require proper maintenance to avoid damage.

- Recommended Article: Read the differences between cement blocks and interlocking blocks.

Difference Between Interlocking Blocks and Cement Blocks

?Which is Better: Cement Blocks or interlocking Bricks

Given the topics discussed above, it is natural for this question to arise in your mind: Are interlocking bricks better or cement blocks? In fact, the answer to this question completely depends on your needs and the type of structure you are building.

For example, if you want a structure that is resistant to earthquakes, fire, and pressure, interlocking bricks are undoubtedly a much better option. Additionally, interlocking bricks have an aesthetically pleasing appearance, which can be used as a facade, reducing facade costs.