Blog

Fly Ash Brick

Fly Ash Brick

(Characteristics, Applications, and Disadvantages)

In this article, we will examine and introduce fly ash brick, which is one of the newest types of building materials, and discuss its raw materials, characteristics, and applications.

Fly ash bricks have been introduced to the market as a replacement for clay bricks, which are far superior and more advanced than ordinary bricks. These types of bricks offer more benefits to contractors compared to clay bricks, making them a desirable option for construction. Additionally, fly ash bricks play a significant role in environmental preservation and help conserve natural resources.

What is Fly Ash?

Before introducing fly ash bricks, let’s first examine the primary component, which is fly ash. Fly ash is a pozzolanic additive. These types of additives do not have cementitious properties on their own. However, when mixed with lime and exposed to moisture, they acquire cementitious properties.

According to the definition in the ninth chapter of the National Building Regulations, fly ash is defined as follows: Fly ash is a byproduct of coal combustion, which includes materials such as silica, alumina, and oxides of calcium and iron. Several factors can affect the properties and quality of fly ash, with the most important ones being the type of coal and its composition, combustion conditions including temperature and the amount of oxygen needed for burning, the mill used for crushing coal, the type of furnace, and even the cooling rate of particles. After the particles cool down, special filters collect the fly ash as dust. The beneficial effects of this material include improving its fresh and hardened properties.

Suggested article: What brick should we use for our construction?

Fly Ash Bricks

Fly ash bricks are one of the building materials made from Class C and Class F fly ash, which are compressed under a pressure of 28 MPa or 272 atm They are then placed in a steam bath at a temperature of 66 ° Celsius for 24 hours and are hardened by an air entrainment agent. After that, the fly ash bricks undergo over 100 freeze-thaw cycles. These types of bricks have a high concentration of calcium oxide, which is why they are also known as “self-cementing” bricks. The manufacturing process through which fly ash bricks are produced is more cost-effective compared to other clay bricks and also helps in reducing energy consumption and mercury pollution. The use of coal waste has been common even in the past, collected from homes and utilized locations as waste. Coal ash was also collected and delivered to local brick kilns to produce high-quality bricks by mixing it with clay.

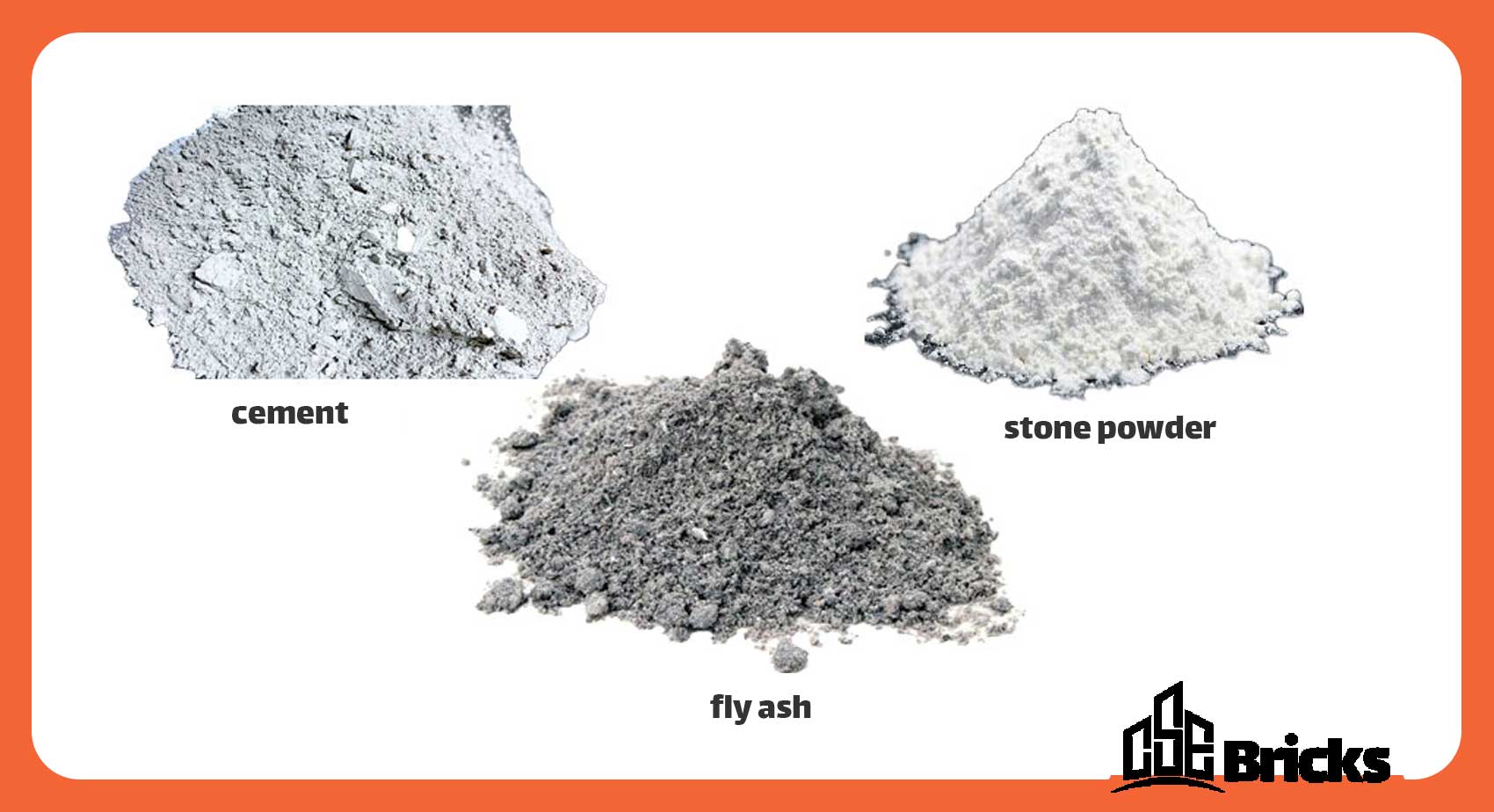

Raw Materials for Producing Fly Ash Bricks:

- Fly Ash (60%)

- Stone or Sand Powder (30%)

- Portland Cement (10%)

Characteristics of Fly Ash Bricks

These bricks have a uniform cement-like color and do not require plastering. They do not conduct heat and act as an insulator against temperature and sound. Due to their structure, fly ash bricks do not allow the passage of fire and flames. These building materials are very durable and have a moisture absorption rate of 6 to 12 percent, which provides good resistance to moisture.

Applications of Fly Ash

In addition to being a primary material in the production of many cement products such as bricks, fly ash is used in the construction of concrete blocks and concrete pouring. Its other common uses include concrete pavements or PCC (Portland Cement Concrete) pavements.

Furthermore, in road construction projects that use PCC, a significant amount of concrete is needed; therefore, substituting fly ash is much more economical. Fly ash is also used in filling and backfilling mines.

Disadvantages of Fly Ash Bricks

- Not all fly ash bricks have the required quality for construction. Most bricks produced in power plants are similar to concrete; however, other bricks need refinement. To prevent these disadvantages in bricks, high-quality fly

ash must be used.

- The curing process of the brick is also of great importance. If not done properly, the brick will not have the suitable quality for construction. Bricks that do not have sufficient quality can negatively affect concrete and, by increasing permeability, can cause damage to the structure.

- Fly ash bricks have a smoother and softer surface compared to clay bricks. Therefore, these bricks have less adhesion to concrete.

- These bricks are only suitable for use in tropical or semi-tropical regions because fly ash bricks do not absorb heat.

What is the impact of fly ash on the environment and technology?

Fly ash alone can have detrimental effects on the environment and human health. Therefore, its disposal should be prioritized as one of the most important actions in preserving the environment. In the past, fly ash was released into the atmosphere, causing air pollution. However, nowadays, fly ash is collected using electrostatic precipitators to prevent its dispersion in the atmosphere and is utilized in the industry. Additionally, fly ash strengthens and enhances the quality of concrete, attracting the attention of concrete technologists and government companies.