Blog

Types of Tests and Standards for Interlocking Bricks Worldwide

Types of Tests and Standards for Interlocking Bricks Worldwide

Today, there is a high demand for affordable construction, which can be met by producing low-cost and environmentally friendly materials. One of the most common methods in this field is the use of compressed blocks or interlocking bricks for building units. Although extensive research has been conducted to develop and standardize such materials, there is still a need for a better understanding of the physical and mechanical properties of interlocking bricks under various service conditions to assess the durability of such building units. This article examines the tests and standards for interlocking bricks globally.

Cement: The Best Stabilizing Material

In the experimental program designed for this post, samples were categorized based on different ratios of silt, sand, and stabilizing materials. The stabilizing materials used include cement, bitumen, and white gluten. Additionally, the samples were tested under compression to determine compressive strength on days 7 and 28. Furthermore, the samples were tested to determine the water absorption rate of each mix, and the results show that cement is the best stabilizing material among the materials examined. There is a specific percentage of stabilizing material that creates maximum compressive strength, and beyond that, adding more stabilizing material reduces compressive strength.

Compressive Strength Test of Interlocking Bricks

It is worth mentioning that all samples have been tested under pressure using a universal testing machine. standard tests for interlocking bricks were conducted according to ASTM C109. The tested timeframe for the samples was on days 7 and 28 after the production of the samples.

The strength of the tested samples is shown using a coding system, and the adopted coding system is as follows:

- The first character (number) indicates the percentage of silt in the samples.

- The second character (letter) specifies the type of stabilizer. (Cement C, Bitumen B, Gluten G)

- The third character (number) represents the percentage of stabilizer in the sample.

- The fourth character (letter) indicates the soil condition. (Fine F, Coarse C)

- The fifth character (number) shows the number of samples in this category.

| Average Compressive Strength (28 days) |

Average Compressive Strength (7 days) |

coding |

| 10.8±0.7 | 7.0±0.2 | 50-C-10-C |

| 10.3±0.2 | 5.7±0.3 | 50-C-7.5-C |

| 8.2±0.2 | 5.2±0.4 | 50-C-5-C |

| 6.0±0.3 | 4.8±0.1 | 50-C-2.5-C-A |

| – | 6.7±0.1 | 50-C-0-C |

| – | 6.9±0.4 | 40-C-10-C |

| – | 5.7±0.2 | 40-C-5-C |

| – | 6.4±0.2 | 40-C-0-C |

| – | 6.4±0.4 | 30-C-10-C |

| – | 4.8±0.2 | 30-C-5-C |

| – | 6.0±0.2 | 30-C-0-C |

| – | – | 50-C-10-F |

| – | 7.6±0.2 | 50-C-7.5-F |

| 9±2.12 | 4.7±0.1 | 50-C-5-F |

| 12.7±3 | 5.2±0.2 | 50-C-2.5-F-1 |

| 10.0±0.2 | 4.0±.6 | 50-B-3.75-F |

| 6.8±0.6 | 7.8±0.3 | 50-G-3.75-F |

Compressive Strength Test of Interlocking Bricks

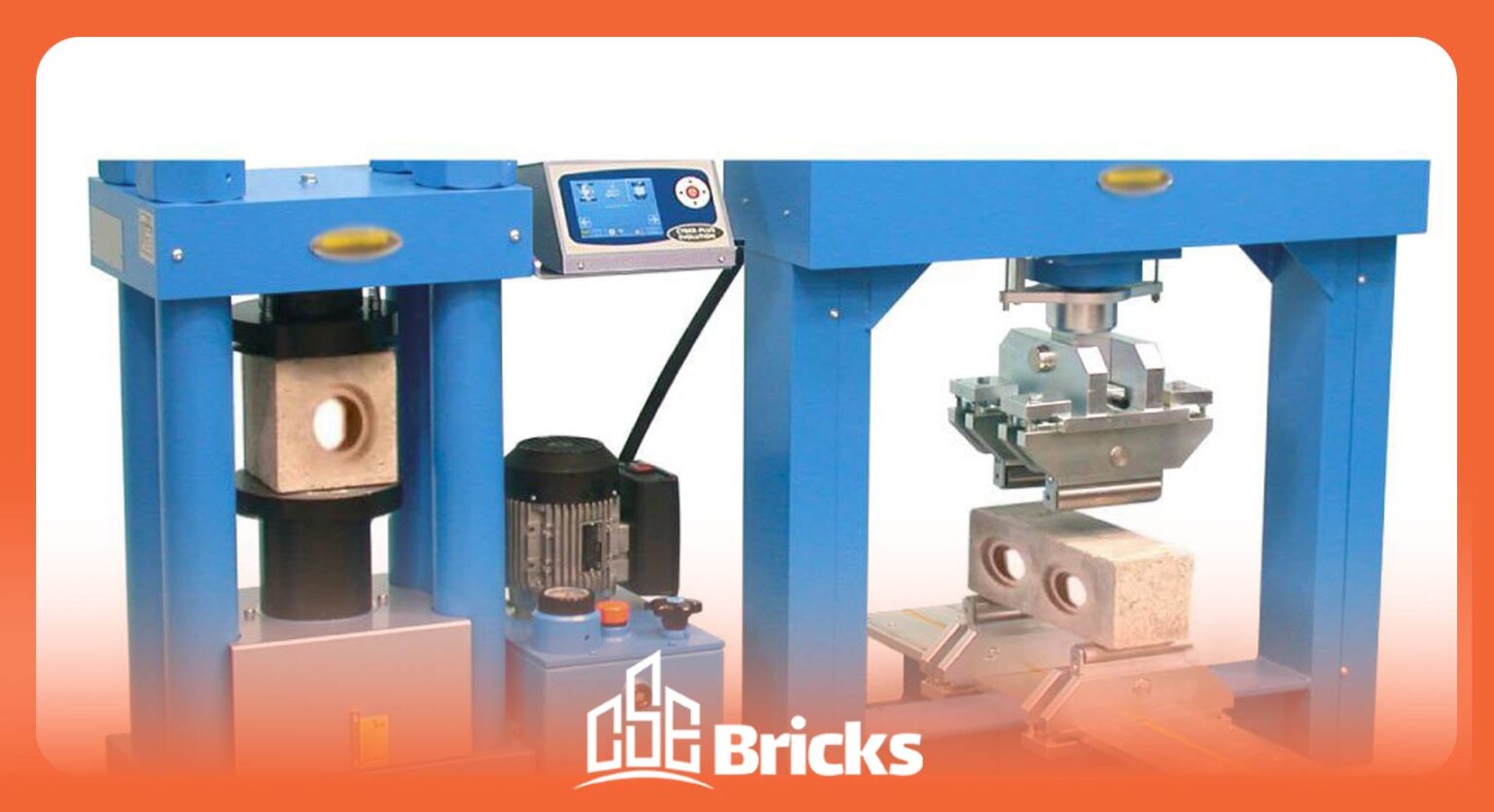

The compressive strength test was conducted according to the BS EN 772-11 standard using the (CONTROLS 50- C46G2) testing machine with a maximum capacity of 2000 kN at a rate of 0.05 N/mm² until the block broke. The maximum load applied to each broken block was recorded, and the compressive strength of the blocks was determined. The tensile splitting strength test was conducted according to the BS EN 12390-6 brick standard using the (CONTROLS 50-C46G2) testing machine. Splits were placed in the center of the top and bottom of the interlocking brick. Continuous loading was applied at a rate of 0.05 N/mm² until the brick failed.

For samples using gluten or bitumen as binding materials, they were tested on day 7; there was no need to test the samples on day 28 because these materials do not require time to gain strength like others. The 7-day compression tests showed that the mix containing 50% ground silt, 7.5% cement, and 42.5% sand had the highest compressive strength among all samples.

When comparing the 7-day and 28-day results, initially, the gluten samples showed better results; however, by the end of the 28th day, the cement samples demonstrated their superiority.

The conclusion is that in the early days, the cement was not fully hydrated; however, after full hydration, the samples nearly achieved their full strength and surpassed the strength of the gluten samples. It should be noted that the compressive strength of interlocking bricks composed of 50% ground silt and 7.5% cement exceeded the limits specified in the Egyptian standard ES:1292-1/2015 for load-bearing concrete masonry units, as well as the standard ES4763/2006 for masonry units made of clay bricks.

Water Absorption Test of Interlocking Bricks

The water absorption of interlocking bricks was carried out using two different techniques. The first was according to ASTM C1585 for samples where cement was used as a stabilizing material. Although differences in water content ratios (from 13% to 16.8%) were observed:

Samples with lower water percentages weighed less than those with higher water percentages. This can be explained by the fact that voids (samples had different volumes and weights) were filled with water, leading to high absorption. The compaction can vary from one sample to another. In this test, samples using bitumen or gluten as stabilizing materials completely failed. The reason for this failure could be attributed to the negative effects of temperature, as the temperature reduces the adhesive properties of the materials.

|

Sample Code |

| 14.8 ± 0.15 | 50-C-7.5-N |

| 16.8 ± 0.57 | 50-C-10-G |

| 13 ± 0.30 | 50-C-2.5-N |

| 14.3 ± 0.38 | 50-C-5-G |

| 16.7 ± 3.1 | 50-C-2.5-G |

| 15.3 ± 0.58 | 50-C-5-N |

| F** | 50-G-3.75-G |

| F* | 50-B-3.75-G |

.F*: Only two samples failed the water absorption test

.F: Failed the water absorption test

Capillary Absorption Test of Interlocking Bricks

To evaluate the impact of rain and storms on interlocking bricks, the capillary absorption test is considered more realistic. As a result, this test is used as the second technique. Based on the African regional standard for compressed earth blocks, the table below shows the results of the capillary absorption test:

This test for interlocking bricks measures the absorption of samples by calculating the absorption coefficient, which relates to the rate of absorption. Here is an example table format to represent the test results.

| absorption coefficient (min/gm/cm²) |

coding | # |

| 7.6 | 50-C-7.5-N | 1 |

|

12.7 |

50-C-10-G | 2 |

| 6.3 | 50-C-10-G | 3 |

| 15.2 | 50-C-5-G | 4 |

| 10.1 | 50-C-2.5-G | 5 |

| 10.1 | 50-C-5-N | 6 |

| 2.5 | 50-G-3.75-G | 7 |

| 10.1 | 50-B-3.75-G | 8 |

Effect of Fine Silt in Interlocking Brick Tests

For the 7-day compressive strength test, samples with 7.5% cement showed a significant increase in pressure strength (33%) when the silt was ground, while samples with 2.5% cement showed only an 8% increase in compressive strength, which is very negligible. In contrast, samples with 5% cement experienced a significant 20% decrease in compressive strength when ground silt was used.

On the other hand, all 28-day samples with 2.5%, 5%, and 7.5% cement content showed increased compressive strength when the silt was ground, except for samples with 10% cement content, which showed increases of 13%, 21%, and 23% in compressive strength. However, samples with 10% cement content had a 5% decrease in compressive strength, which is very negligible.

Density Test of Interlocking Bricks

Water absorption through the capillary absorption test was recorded according to the BS EN 772-11 standard for naturally dried blocks after 28 days.

The mass of the samples, which were 280*140 mm to a depth of 5 mm, was measured, and they were immersed in a fixed water bath for 10 minutes. The absorbed mass of the samples was measured and recorded, and then the water absorption rate through capillary action was determined.

The water absorption after 24 hours ranged from 8% to 12%. The apparent density of these blocks varied between 1800 to 2000 kg/m³.

Dimensions of Interlocking Bricks and Blocks

Interlocking bricks are available in dimensions of 812.525 cm, and interlocking blocks are available in dimensions of 101530 cm in the Iranian market. The diameter of the hole on the brick is 5 cm. It is possible to slightly alter the dimensions of interlocking bricks and blocks. For more information and consultation, you can contact the support team at csebrick.com.

csebrick.com offers various interlocking brick machines with up to 30 different molds. You can produce bricks without the need for a kiln and fuel. For more information, please contact us.

Standards for Interlocking Bricks and Blocks

Soil-based construction methods have over 4000 years of history, and interlocking bricks are a way of producing bricks utilizing knowledge and experience to protect the environment and energy resources. This method has come a long way and now has the potential for broader applications. Many reported failures of buildings are mainly due to a lack of understanding of parameters, absence of brick standards, specifications, and poor-quality control. Any innovative method should develop standards and specifications before applications. Experimental programs should not be carried out without brick standards and specifications.

As shown in the table below, interlocking bricks and blocks have brick standards in most parts of the world. In Iran, they also have an ISIC code and are included in the 8th chapter of national building regulations and the relevant encouraging standard for production.

In this article, we examined various tests and standards for interlocking bricks worldwide. If you have any questions regarding obtaining standards or conducting brick tests, please fill out the form below. Our experts will respond to you at the earliest opportunity.