Blog

Weight of Interlocking Brick

Weight of Interlocking Brick

Factors Affecting It

Interlocking Bricks and Blocks are also known as Lego Bricks and are used in many constructions such as building structures, gazebos, pools, garden walls, etc. In this article, we will examine the weight of interlocking bricks and the factors that can affect it.

?What is Interlocking Brick

Before examining the weight of this type of building material, let’s have a brief overview of what interlocking brick is. Interlocking brick is a type of building material that forms a structure through its male and female properties and by interlocking with each other. The production method of this brick involves combining raw materials and pressing them to form a cohesive brick. In fact, kilns are not used in the production of interlocking bricks and blocks; therefore, it does not harm the environment.

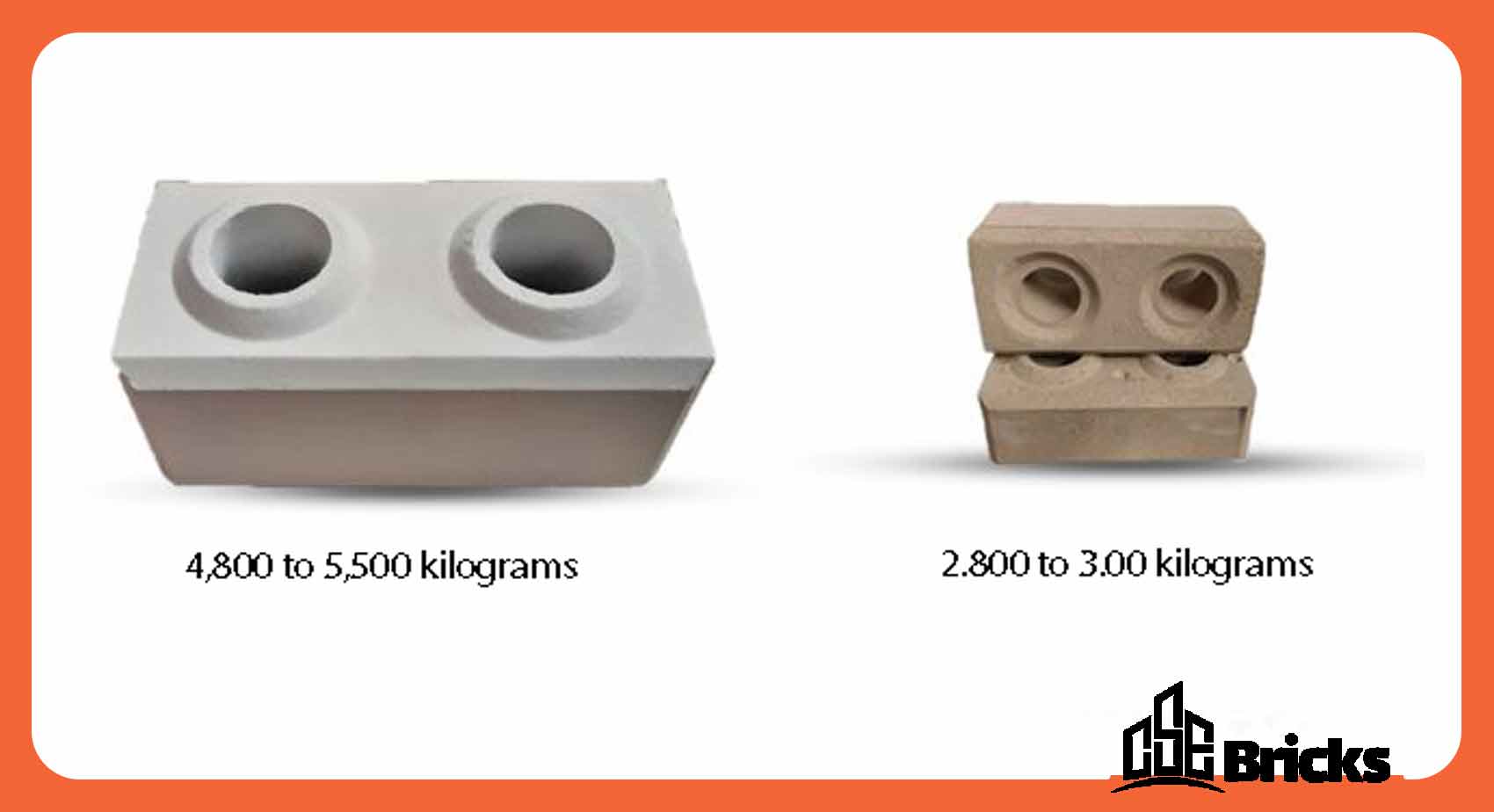

Weight of Interlocking Bricks and Blocks

Interlocking bricks and blocks are produced using fully automatic machines. The approximate weight of interlocking bricks produced by experienced brick production lines ranges from 2.800 to 3.00 kilograms. The weight of interlocking blocks produced can vary from 4.800 to 5.500 kilograms. In fact, the weight of these building materials can vary and this is entirely dependent on the raw materials used in their production. Therefore, we will examine these influencing factors in the following sections.

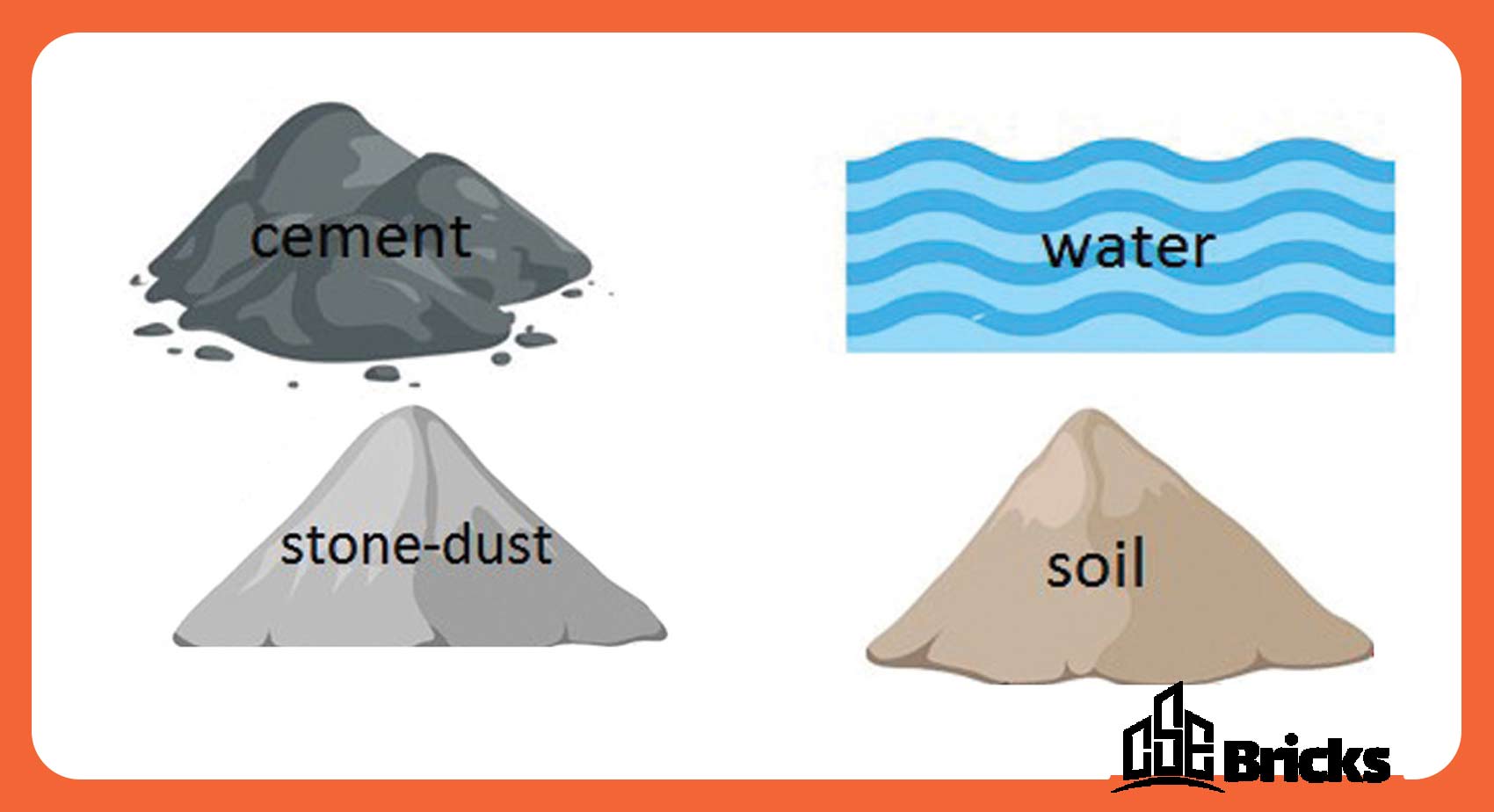

Raw Materials Affecting the Weight of Interlocking Bricks

The raw materials for interlocking bricks are:

- Waste and residue from sand mines or stone-cutting factories (70%)

- Cement (20%)

- Stone powder (10%)

- Color powder (optional)

- Water

As mentioned earlier, interlocking bricks are formed by combining and compacting these materials. The primary component, which is waste, has the greatest impact on the weight of the interlocking brick. In fact, the denser the main material, the heavier the overall weight of the Lego brick will be. For example, if stone waste is used, the final weight of the interlocking brick and block will be higher. However, using soil materials reduces the weight. Additionally, the percentage of cement and stone powder mixed with other materials also affects the weight of the interlocking brick and block.

A Few Important Points

Here are some important points about interlocking bricks and their texture, which can be very useful if you have started an interlocking brick production line:

- Cement bonds with a stony texture, but it does not bond with a soil texture.

- The texture of fine sand in interlocking bricks causes them to bulk up and act like a filler.

- The presence of lime and silicon helps interlocking bricks to gain better consistency.

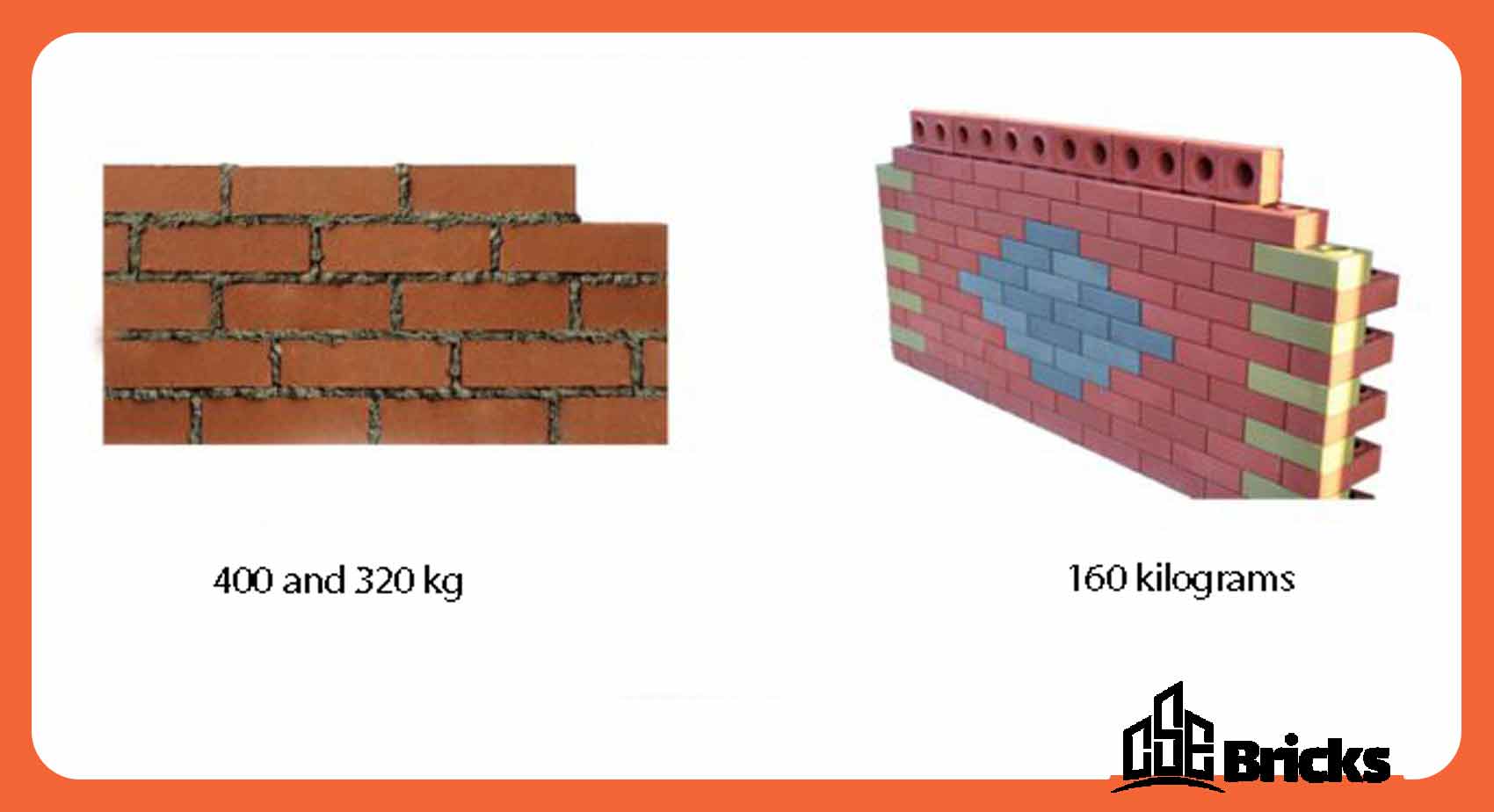

Weight of Interlocking Brick in Wall Construction

Weight of Interlocking Bricks in Wall Construction The weight of a single interlocking brick is higher compared to standard bricks such as solid clay bricks and hollow bricks, which typically weigh between 1 to 1.5 kilograms. However, the total weight of interlocking bricks in constructing one square meter of wall is about half that of these standard bricks. The total weight of interlocking bricks in one square meter comes to approximately 160 kilograms, whereas the total weight for solid clay bricks and hollow bricks in the same area is 400 kilograms and 320 kilograms, respectively.