Blog

History of Brick

History of Brick

From Hand-Made Brick to interlocking Brick

You might be wondering about the history of brick making and where it has been used. Additionally, you might be curious about the methods of firing and transporting bricks that have been used in construction to this day. Well, you’ve come to the right place; because in this article, we will provide a comprehensive review of the history of bricks.

From Handmade Bricks to Interlocking Bricks

As the history of bricks evolved, nomads by the riversides noticed that the bricks used in their hearths gained a more robust texture due to the fire’s flames. As a result of this discovery, mixed materials began to be fired, giving rise to the production of kiln-baked bricks.

For nearly 7,000 years, handmade bricks—often referred to as “pressed bricks”—have played a vital role in construction.Throughout history, these durable and visually appealing bricks have been employed to strengthen and decorate palaces, mosques, schools, and various other structures.

However, despite the many advantages of modern bricks such as interlocking bricks over traditional ones like handmade and perforated bricks, the traditional handmade brick industry is taking its last breaths. In today’s world, it is possible to easily produce various interlocking bricks and blocks in different sizes and colors without the need for a kiln using interlocking brick production machines. This makes them ready for use in a short time.

Bricks in Ancient Iran

The art of working with bricks has held significant value in Iran’s history. In Iranian architecture, bricks were used not only in walls but also for arches, roof coverings, facades, and flooring. Today, interlocking bricks have gained much popularity in construction and architecture in Iran due to their numerous advantages.

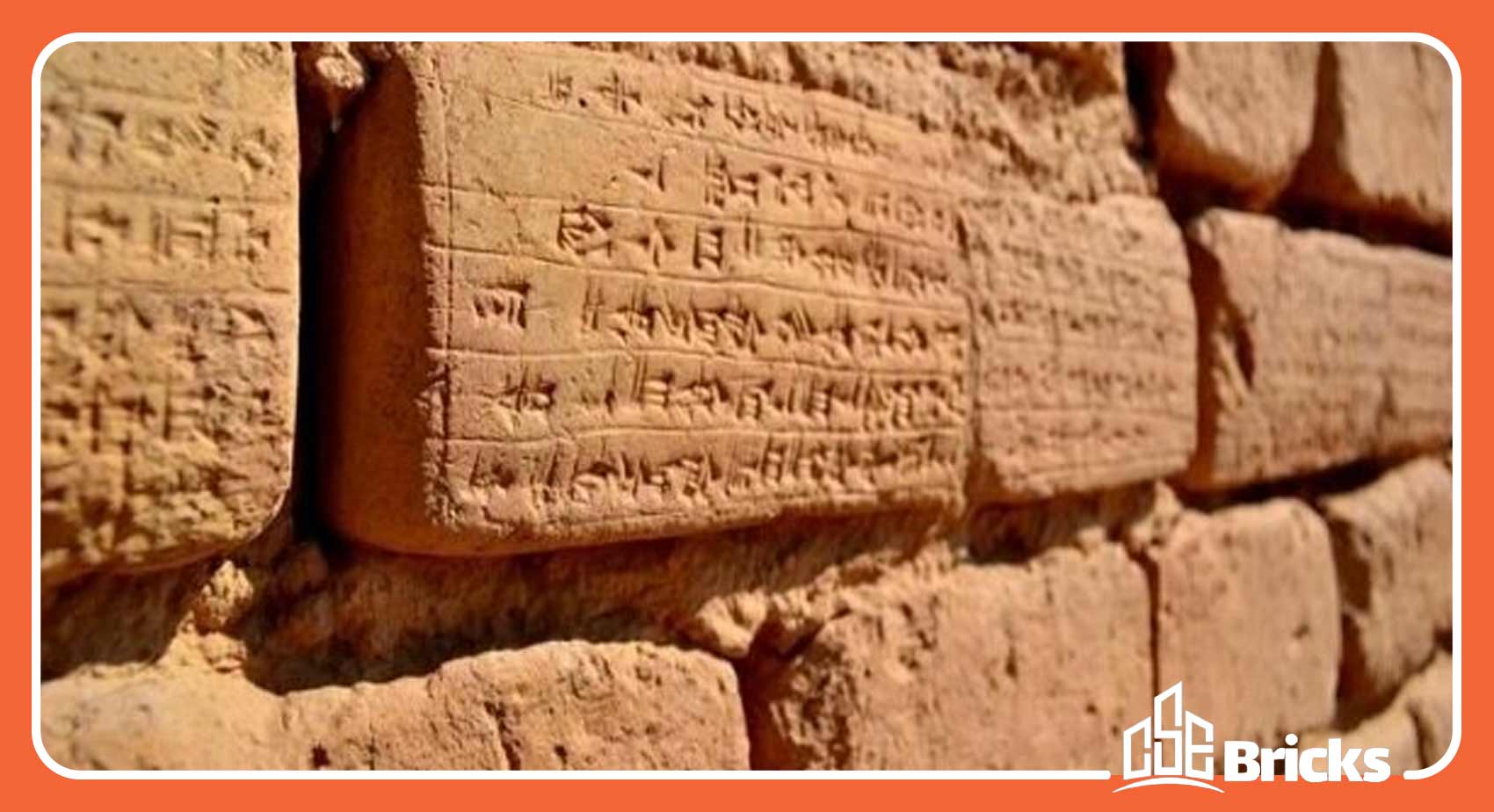

According to archaeologists, with brick structures over 6000 years old found in Khuzestan and Ilam, the Taq Kasra, remains of pottery and brick kilns in Susa, and the Sialk hills in Kashan—showing an ancient history of pottery and

brick-making—it is possible to say that bricks were invented by Iranians and the inhabitants of Mesopotamia.

In ancient Iran, brick-making flourished in areas with good-quality clay. However, in today’s world, with the advent of interlocking bricks, you are not limited by raw materials. The availability of raw materials allows for the efficient and standardized production of interlocking bricks in various types and with high profitability. Since the production of interlocking bricks does not require a firing kiln, it helps to prevent energy waste and air pollution.

Brick Dimensions

Bricks have been produced in various shapes and sizes throughout different historical periods. For instance, Elamite bricks were produced with dimensions of 100 x 380 x 380 millimeters. In contrast, during the Sassanid era, bricks had dimensions of 440 x 440 x 70 to 80 millimeters, which were later reduced to 200 x 200 x 30 to 40 millimeters. Brick production and usage became more prevalent during the Sassanid period, and they were utilized in larger and more significant structures.

Khatai bricks were a specific type of brick measuring 50 x 250 x 250 millimeters. These bricks were used for various construction purposes, including flooring, roofing, and facades of clay walls. Prior to World War I, Russians manufactured Kazakh bricks, which measured 50 x 100 x 200 millimeters. In the modern construction world, you can use the pattern of interlocking brick paving to enjoy its stunning appearance.

In this section, we delve into the historical process of brick firing.In the era before modern kilns, bricks were arranged in clamps by stacking them one over another. After covering the clamp with soil, firewood was ignited under the clamp to heat the bricks until they were fully fired. Following this stage, the bricks were sorted based on their degree of firing and used for construction purposes. Bricks that were sufficiently fired and had an appealing color were used for building facades, while softer bricks that received less heat were used as support bricks. However, some bricks that were farther from the heat source were discarded.

The interlocking brick production machine provides you with the opportunity to create beautiful facades according to your taste. By adding and mixing color powder with the raw materials, you can easily produce various types of interlocking bricks with diverse mineral or chemical colors, making them ready for use.

Brick Firing Stages

The firing process for various types of bricks, such as refractory bricks, decorative bricks, etc., is generally the same. However, to produce different types of bricks, specific materials are added to the clay before placing it in the kiln.

The general brick firing process includes the following steps:

- Preparing raw materials

- Integrating soil

- Producing mud (wet mix)

- Molding

- Drying

Three Types of Brick Kilns

Brick firing is generally done in two types of kilns: periodic kilns and tunnel kilns.

-

Shaft Kilns (Stationary Brick and Fire)

Shaft kilns feature a large-diameter, short-height furnace. Inside the kiln, bricks are placed in a circular formation with small gaps, creating a tower-like shape that enables the fire to transform raw bricks into fired ones.

-

Hoffmann Kiln (Stationary Brick and Moving Fire)

The Hoffmann kiln is designed in a ring shape and features a high, continuous structure. Bricks are arranged along the length of the kiln, and by moving the fire, the raw bricks are fired and converted into finished bricks.

-

Tunnel Kiln (Moving Brick and Stationary Fire)

In tunnel kilns, there is a fiery tunnel in the center that is fueled by gas. Raw bricks enter through the entrance of the tunnel and are gradually fired as they move through, emerging as finished bricks at the exit.

Different Types of Bricks

Throughout different historical periods, bricks have been creatively transformed in terms of color and shape based on their needs and applications. Here are a few examples:

- Interlocking Brick

- Refractory Brick

- Absorptive Brick

- Washed Brick

- Sponge Brick

- Bahmani Brick

- Thin Brick

- Lead Brick

- Flat Brick

- Trimmed Brick

- Welded Brick

- Square Brick

- Perforated Brick

- Khatai Brick

- Lego Brick

- Double Brick

- Centimeter Brick

- Green Yellow Brick

- Thin Ends Brick

- Clay Brick

- Three-centimeter Brick

- Cement Brick

- Paving Brick

- Pressed Brick

- Red Brick

- Kazakh Brick

- Lock Brick

- Pen Brick

- Waterproof interlocking Brick

- Defective Brick

- Edge Brick

- Lying and Standing Brick

- Pressed Brick

- Tile

- Crow Flight Brick

- Glazed Brick

- Lime Brick

- Mosaic

- Narrow Brick

- Nizami Brick

- Facade Brick

- Two-sided Facade Brick

- Stamped Brick

- Yellow Brick

- Three-double Brick

- …and more.

Absolutely! The variety and historical development of bricks are truly remarkable. I’m excited to delve deeper into the details of different types of bricks, including interlocking bricks, in our future discussions.

History of Brick Transportation from Past to Present

Transporting Bricks with Mules and Carts

Until around 1951, brick transportation was done using four-wheeled carts, mules, and donkeys. Major material sellers had several donkeys and a stable next to their supply stores. Eventually, trucks replaced these traditional methods, significantly speeding up brick transportation. In the past, workers would carefully pass bricks hand-to-hand to load them onto trucks. Eventually, electric conveyors became a useful and speedy replacement for manual labor, enhancing the efficiency of brick transportation.

Transporting Bricks with Edge Trucks

Today, the loading of bricks varies based on the type, weight, and dimensions of the bricks. Unpackaged bricks, such as clay bricks and large Lefton bricks, which are at risk of falling off the sides of the truck, are generally transported using edge trucks. Some bricks, like rough bricks and small Lefton mold bricks, are unloaded with trailers or ten-wheel dump trucks. These types of vehicles are cost-effective as they unload bricks in one go, eliminating the need for labor costs associated with unloading.

Transporting Interlocking Bricks with Edge-less Trucks

There are also edge-less transit trucks that are used for transporting materials that are not at risk of falling off. TTrucks of this type are ideal for carrying palletized or packaged bricks, including interlocking varieties. Each pallet typically contains 480 interlocking bricks, which can be used for 10 square meters. Pickup trucks can also be used to move smaller loads of interlocking bricks that are shrink-wrapped. By using this packaging approach, transporting interlocking bricks becomes simpler and more economical.